TPS7A11

TPS7A11

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER

2020

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

www.ti.com

TPS7A11 500-mA, Low VIN, Low VOUT, Ultra-Low Dropout Regulator

1 Features

3 Description

•

•

The TPS7A11 is an ultra-small, low quiescent current,

low-dropout regulator (LDO). This device can source

500 mA with an outstanding ac performance (load and

line transient responses). This device has an input

range of 0.75 V to 3.3 V, and an output range of 0.5 V

to 3.0 V with a very high accuracy of 1.5% over load,

line, and temperature. This performance is ideal for

supplying power to the lower core voltages of modern

microcontrollers (MCUs) and analog sensors.

•

•

•

•

•

•

•

Ultra-low input voltage range: 0.75 V to 3.3 V

Ultra-low dropout for minimum power loss:

– 140 mV (maximum) at 500-mA DRV package

– 110 mV (maximum) at 500-mA YKA package

Low quiescent current:

– VIN IQ = 1.6 µA (typical)

– VBIAS IQ = 6 µA (typical)

1.5% accuracy over load, line, and temperature

High PSRR: 64 dB at 1 kHz

Available in fixed-output voltages:

– 0.5 V to 3.0 V (in 50-mV steps)

VBIAS range: 1.7 V to 5.5 V

Packages:

– 2.0-mm × 2.0-mm WSON (6)

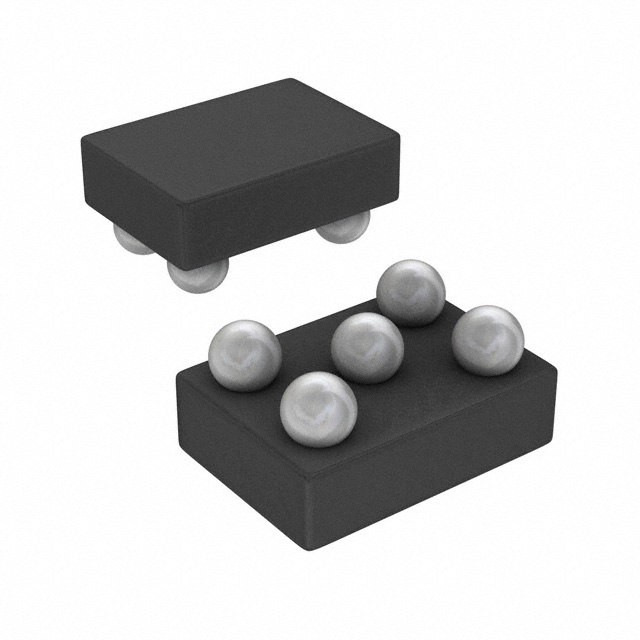

– 0.74-mm × 1.09-mm DSBGA (5)

Active output discharge

2 Applications

•

•

•

•

•

•

Smart watches, fitness trackers

Wireless headphones and earbuds

Camera modules

Smart phones and tablets

Portable medical devices

Solid state drives (SSDs)

The TPS7A11 is equipped with an active pulldown

circuit to quickly discharge the output when disabled,

and provides a known start-up state.

The TPS7A11 is available in a small 2.00-mm × 2.00mm WSON, 6-pin (DRV) package and an ultra-small

0.74-mm × 1.09-mm, 5-pin DSBGA (YKA) package

that makes the device suitable for space-constrained

applications.

VBATTERY

CBIAS

OUT

Standalone

DC/DC Converter

Or PMU

Device Information (1)

BIAS

IN

IN

VOUT

OUT

CIN

PART NUMBER

COUT

PACKAGE

TPS7A11

EN

GND

The primary power path is through the IN pin and can

be connected to a power supply as low as 140 mV

above the output voltage. This device supports very

low input voltages with the use of an additional VBIAS

rail that is used to power the internal circuitry of the

LDO. The IN and BIAS pins consume very low

quiescent current of 1.6 µA and 6 µA, respectively.

The low IQ and ultra-low dropout features help to

increase the efficiency of the solution in powersensitive applications. For example, the supply

voltage to the IN pin can be an output of a highefficiency, DC/DC step-down regulator and the BIAS

pin supply voltage can be a rechargeable battery.

GND

TPS7A11

(1)

BODY SIZE (NOM)

WSON (6)

2.00 mm × 2.00 mm

DSBGA (5)

0.74 mm × 1.09 mm

(0.35-mm pitch)

For all available packages, see the orderable addendum at

the end of the data sheet.

Typical Application Circuit

140

TJ

40 qC

0 qC

25 qC

Input Voltage Dropout (mV)

120

100

85 qC

105 qC

125 qC

80

60

40

20

0

0

50

100

150

200 250 300 350

Output Current (mA)

400

450

500

Dropout vs IOUT and Temperature, YKA Package

An©IMPORTANT

NOTICEIncorporated

at the end of this data sheet addresses availability, warranty, changes, use in

safety-critical

applications,

Copyright

2020 Texas Instruments

Submit

Document

Feedback

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Product Folder Links: TPS7A11

1

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Pin Configuration and Functions...................................3

6 Specifications.................................................................. 5

6.1 Absolute Maximum Ratings ....................................... 5

6.2 ESD Ratings .............................................................. 5

6.3 Recommended Operating Conditions ........................5

6.4 Thermal Information ...................................................6

6.5 Electrical Characteristics ............................................6

6.6 Typical Characteristics................................................ 8

7 Detailed Description......................................................14

7.1 Overview................................................................... 14

7.2 Functional Block Diagram......................................... 14

7.3 Feature Description...................................................14

7.4 Device Functional Modes..........................................17

8 Application and Implementation.................................. 18

8.1 Application Information............................................. 18

8.2 Typical Application.................................................... 22

9 Power Supply Recommendations................................23

10 Layout...........................................................................24

10.1 Layout Guidelines................................................... 24

10.2 Layout Examples.................................................... 24

11 Device and Documentation Support..........................25

11.1 Device Support........................................................25

11.2 Documentation Support.......................................... 25

11.3 Receiving Notification of Documentation Updates.. 25

11.4 Support Resources................................................. 25

11.5 Trademarks............................................................. 26

11.6 Electrostatic Discharge Caution.............................. 26

11.7 Glossary.................................................................. 26

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision A (December 2018) to Revision B (December 2020)

Page

• Updated the numbering format for tables and figures throughout the document............................................... 1

• Updated sequencing requirement to clarify differences between "A" and "non-A" versions.............................15

• Changed Device Nomenclature table............................................................................................................... 25

Changes from Revision * (September 2018) to Revision A (December 2018)

Page

• Changed YKA (DSBGA) package status from Preview to Production Data ...................................................... 1

• Added Evaluation Module subsection ..............................................................................................................25

2

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

5 Pin Configuration and Functions

OUT

NC

1

6

2 Thermal 5

IN

GND

Pad

EN

3

4

BIAS

Not to scale

TI recommends connecting the SON (DRV) package thermal pad to ground.

NC – No internal connection.

Figure 5-1. DRV Package, 6-Pin SON With Exposed Thermal Pad, Top View

Table 5-1. Pin Functions: DRV

PIN

NAME

NO.

I/O

DESCRIPTION

IN

6

Input

Input pin. A capacitor is required from IN to ground for stability. For best transient response, use

the nominal recommended value or larger ceramic capacitor from IN to ground. Follow the

recommended capacitor value as listed in the Recommended Operating Conditions table. Place

the input capacitor as close to the input pin of the device as possible.

OUT

1

Output

Regulated output pin. A capacitor is required from OUT to ground for stability. For best transient

response, use the nominal recommended value or larger ceramic capacitor from OUT to ground.

Follow the recommended capacitor value as listed in the Recommended Operating Conditions

table. Place the output capacitor as close to the output pin of the device as possible.

GND

5

—

BIAS

4

Input

BIAS pin. This pin enables the use of low-input voltage, low-output voltage (LILO) conditions. For

best performance, use the nominal recommended value or larger ceramic capacitor from BIAS to

ground. Follow the recommended capacitor value as listed in the Recommended Operating

Conditions table. Place the bias capacitor as close to the bias pin of the device as possible.

EN

3

Input

Enable pin. Driving this pin to logic high enables the device. Driving this pin to logic low disables

the device. If enable functionality is not required, this pin must be connected to IN or BIAS;

however, connecting EN to IN is only acceptable if the IN pin voltage is greater than 0.9 V.

NC

2

—

This pin is not internally connected. Connect to ground for better thermal dissipation or leave

floating.

—

Connect the thermal pad to a large-area ground plane.

Thermal pad

Ground pin. This pin must be connected to ground.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

3

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

IN

A1

GND

BIAS

A3

OUT

C3

EN

B2

C1

Not to scale

Figure 5-2. YKA Package, 5-Pin DSBGA, Top View

Table 5-2. Pin Functions: YKA

PIN

NO.

A1

4

NAME

IN

A3

OUT

B2

GND

I/O

Input

DESCRIPTION

Input pin. A capacitor is required from IN to ground for stability. For best transient response, use the

nominal recommended value or larger ceramic capacitor from IN to ground. Follow the recommended

capacitor value as listed in the Recommended Operating Conditions table. Place the input capacitor as

close to the input pin of the device as possible.

Regulated output pin. A capacitor is required from OUT to ground for stability. For best transient

response, use the nominal recommended value or larger ceramic capacitor from OUT to ground. Follow

Output

the recommended capacitor value as listed in the Recommended Operating Conditions table. Place the

output capacitor as close to the output pin of the device as possible.

—

Ground pin. This pin must be connected to ground.

C1

BIAS

Input

BIAS pin. This pin enables the use of low-input voltage, low-output voltage (LILO) conditions. For best

performance, use the nominal recommended value or larger ceramic capacitor from BIAS to ground.

Follow the recommended capacitor value as listed in the Recommended Operating Conditions table.

Place the bias capacitor as close to the bias pin of the device as possible.

C3

EN

Input

Enable pin. Driving this pin to logic high enables the device. Driving this pin to logic low disables the

device. If enable functionality is not required, this pin must be connected to IN or BIAS; however,

connecting EN to IN is only acceptable if the IN pin voltage is greater than 0.9 V.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range unless otherwise noted.(1)

MIN

Voltage

Current

(1)

(2)

Input, VIN

–0.3

3.6

Enable, VEN

–0.3

6.0

Bias, VBIAS

–0.3

6.0

Output, VOUT

–0.3

VIN + 0.3 (2)

Maximum output

Temperature

MAX

UNIT

V

Internally limited

A

Operating junction, TJ

–40

150

°C

Storage, Tstg

–65

150

°C

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under

Recommended Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device

reliability.

The absolute maximum rating is 3.6 V or (VIN + 0.3 V), whichever is less.

6.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001(1)

±3000

Charged-device model (CDM), per JEDEC specification JESD22-C101(2)

±500

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating junction temperature range (unless otherwise noted).

MIN

NOM

MAX

UNIT

VIN

Input voltage

0.75

3.3

VBIAS

Bias voltage

1.7

5.5

V

VOUT

Output voltage

0.5

3.0

V

IOUT

Peak output current

0

500

mA

CIN

Input capacitor

2.2

V

µF

CBIAS

Bias capacitor

COUT (1)

Output capacitor

2.2

22

µF

TJ

Operating junction temperature

–40

125

℃

(1)

0.1

µF

Maximum ESR must be lower than 250 mΩ

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

5

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

6.4 Thermal Information

TPS7A11

THERMAL

METRIC(1)

DRV (WSON)

YKA (DSBGA)

6 PINS

5 PINS

UNIT

RθJA

Junction-to-ambient thermal resistance

77.3

169.4

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

91.6

1.1

°C/W

RθJB

Junction-to-board thermal resistance

41.1

55.4

°C/W

ψJT

Junction-to-top characterization parameter

4.3

1.7

°C/W

ψJB

Junction-to-board characterization parameter

41.0

55.6

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

18.6

N/A

°C/W

(1)

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

6.5 Electrical Characteristics

over TJ = –40°C to +125°C, VIN = VOUT(NOM) + 0.5 V, VBIAS = VOUT(NOM) + 1.4 V, IOUT = 1 mA, VEN = 1.0 V, CIN = 2.2 μF, COUT

= 2.2 μF, and CBIAS = 0.1 μF ( unless otherwise noted); all typical values are at TJ = 25°C

PARAMETER

Nominal accuracy

TEST CONDITIONS

TJ = 25°C

TYP

0.5

–20°C ≤ TJ ≤ 85, DRV package

VOUT(NOM) + 0.5 V ≤ VIN ≤ 3.3 V,

VOUT(NOM) + 1.4 V ≤ VBIAS ≤ 5.5 V,

1 mA ≤ IOUT ≤ 500 mA

-1.25

1.25

–40°C ≤ TJ ≤ 85, YKA package

V

+ 0.5 V ≤ VIN ≤ 3.3 V,

Accuracy over temperature OUT(NOM)

VOUT(NOM) + 1.4 V ≤ VBIAS ≤ 5.5 V,

1 mA ≤ IOUT ≤ 500 mA

-1.25

1.25

–40°C ≤ TJ ≤ 125,

VOUT(NOM) + 0.5 V ≤ VIN ≤ 3.3 V,

VOUT(NOM) + 1.4 V ≤ VBIAS ≤ 5.5 V,

1 mA ≤ IOUT ≤ 500 mA

-1.5

1.5

ΔVOUT / ΔVIN

VIN line regulation

VOUT(NOM) + 0.5 V ≤ VIN ≤ 3.3 V

VBIAS line regulation

VOUT(NOM) + 1.4 V ≤ VBIAS ≤ 5.5 V

ΔVOUT / ΔIOUT

Load regulation

0.1 mA ≤ IOUT ≤ 500 mA

TJ = 25°C, IOUT = 0 mA

Bias pin current

ISHDN(IN)

ICL

6

VBIAS shutdown current

VIN shutdown current

Output current limit

%/V

6

%/A

8

–40°C < TJ < 85°C, IOUT = 0 mA

11

IOUT = 0 mA

14

µA

60

1.6

2.1

–40°C < TJ < 85°C, IOUT = 0 mA

2.3

IOUT = 0 mA

2.6

µA

11

–40°C < TJ < 85°C,

VIN = 3.3 V, VBIAS = 5.5 V, VEN ≤ 0.4 V

400

–40°C < TJ < 125°C,

VIN = 3.3 V, VBIAS = 5.5 V, VEN ≤ 0.4 V

1200

–40°C < TJ < 85°C,

VIN = 3.3 V, VBIAS = 5.5 V, VEN ≤ 0.4 V

1

–40°C < TJ < 125°C,

VIN = 3.3 V, VBIAS = 5.5 V, VEN ≤ 0.4 V

3

nA

µA

VOUT = 0.9 × VOUT(NOM), YKA Package

625

920

1175

VOUT = 0.9 × VOUT(NOM), DRV Package

700

990

1250

Submit Document Feedback

%

%/V

IOUT = 500 mA

ISHDN(BIAS)

%

0.03

IOUT = 500 mA

Input pin current(1)

UNIT

0.001

0.2

3

TJ = 25°C, IOUT = 0 mA

IQ(IN)

MAX

-0.5

ΔVOUT / ΔVBIAS

IQ(BIAS)

MIN

mA

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

6.5 Electrical Characteristics (continued)

over TJ = –40°C to +125°C, VIN = VOUT(NOM) + 0.5 V, VBIAS = VOUT(NOM) + 1.4 V, IOUT = 1 mA, VEN = 1.0 V, CIN = 2.2 μF, COUT

= 2.2 μF, and CBIAS = 0.1 μF ( unless otherwise noted); all typical values are at TJ = 25°C

PARAMETER

ISC

TEST CONDITIONS

Short circuit current limit

VDO(IN)

VDO(BIAS)

VIN dropout

voltage(2)

VBIAS dropout voltage(2)

MIN

VOUT = 0 V

VBIAS PSRR

Vn

Output voltage noise

VUVLO(BIAS)

Bias supply UVLO

VUVLO_HYST(BIAS)

Bias supply hysteresis

VUVLO(IN)

Input supply UVLO

VUVLO_HYST(IN)

Input supply hysteresis

tSTR

Start-up time(3)

VHI(EN)

EN pin logic high voltage

VLO(EN)

EN pin logic low voltage

UNIT

mA

VIN = VOUT(NOM) – 0.1 V, IOUT = 500 mA,

YKA package

70

110

VIN = VOUT(NOM) – 0.1 V, IOUT = 500 mA,

DRV package

90

140

IOUT = 500 mA

0.85

1.2

IOUT = 250 mA

0.75

1.0

mV

V

64

f = 100 kHz,

VIN power-supply rejection VOUT = 1.0 V, IOUT = 50 mA

ratio

f = 1 MHz,

VOUT = 1.0 V, IOUT = 50 mA

VBIAS power-supply

rejection ratio

MAX

300

f = 1 kHz,

VOUT = 1.0 V, IOUT = 50 mA

VIN PSRR

TYP

37

dB

31

f = 1.5 MHz,

VOUT = 1.0 V, IOUT = 50 mA

35

f = 1 kHz,

VOUT = 1.0 V, IOUT = 500 mA

56

f = 100 kHz,

VOUT = 1.0 V, IOUT = 500 mA

43

f = 1 MHz,

VOUT = 1.0 V, IOUT = 500 mA

33

Bandwidth = 10 Hz to 100 kHz,

VOUT = 1.0 V, IOUT = 50 mA

dB

93.9

µVRMS

VBIAS rising

1.46

1.54

1.63

VBIAS falling

1.35

1.44

1.55

VBIAS hysteresis

80

mV

VIN rising

645

675

710

VIN falling

565

600

640

VIN hysteresis

75

525

V

mV

mV

1200

µs

0.4

V

0.9

V

IEN

EN pin current

EN = 5.5 V

10

nA

RPULLDOWN

Pulldown resistor

VBIAS = 3.3 V, P version only

120

Ω

TSD

Thermal shutdown

temperature

Shutdown, temperature rising

160

Reset, temperature falling

145

(1)

(2)

(3)

°C

This is the current flowing from VIN to GND.

Dropout is not measured for VOUT < 1.0 V.

Startup time = time from EN assertion to 0.95 × VOUT(NOM).

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

7

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

6.6 Typical Characteristics

at operating temperature TJ = 25°C, VIN = VOUT(NOM) + 0.5 V, VBIAS = VOUT(NOM) + 1.4 V, IOUT = 1 mA, VEN = VIN, CIN = COUT

= 2.2 µF, and CBIAS = 0.1 µF (unless otherwise noted)

0.4

0.4

Change in Output Voltage ( )

0.3

0.2

85 qC

105 qC

125 qC

0.1

0

-0.1

-0.2

TJ

40 qC

0 qC

25 qC

0.3

Change in Output Voltage ( )

TJ

40 qC

0 qC

25 qC

-0.3

0.2

0.1

0

-0.1

-0.2

-0.3

-0.4

0

50

100

150

200 250 300 350

Output Current (mA)

400

450

-0.4

1.4

500

1.6

1.8

DRV package

2.2 2.4 2.6

Input Voltage (V)

2.8

3

3.2

3.4

Figure 6-2. Output Accuracy vs VIN and Temperature

140

0.4

0.2

85 qC

105 qC

125 qC

0.1

0

-0.1

-0.2

TJ

40qC

0qC

25qC

120

Input Votage Dropout (mV)

TJ

40 qC

0 qC

25 qC

0.3

Change in Output Voltage ( )

2

YKA package

Figure 6-1. Output Accuracy vs IOUT and Temperature

100

85qC

105qC

125qC

80

60

40

20

-0.3

-0.4

0

0

50

100

150

200 250 300 350

Output Current (mA)

400

450

500

0

50

100

YKA package

150

200 250 300 350

Output Current (mA)

400

450

500

DRV package

Figure 6-3. Output Accuracy vs IOUT and Temperature

Figure 6-4. VIN Dropout vs IOUT and Temperature

140

0.25

TJ

40 qC

0 qC

25 qC

100

TJ

40 qC

0 qC

25 qC

0.2

85 qC

105 qC

125 qC

Change in Output Voltage ( )

120

Input Voltage Dropout (mV)

85 qC

105 qC

125 qC

80

60

40

20

0.15

85 qC

105 qC

125 qC

0.1

0.05

0

-0.05

-0.1

-0.15

-0.2

-0.25

0

0

50

100

150

200 250 300 350

Output Current (mA)

400

450

500

2

2.5

3

3.5

4

Bias Voltage (V)

4.5

5

5.5

YKA package

Figure 6-5. VIN Dropout vs IOUT and Temperature

8

Figure 6-6. Output Accuracy vs VBIAS and Temperature

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

6.6 Typical Characteristics (continued)

at operating temperature TJ = 25°C, VIN = VOUT(NOM) + 0.5 V, VBIAS = VOUT(NOM) + 1.4 V, IOUT = 1 mA, VEN = VIN, CIN = COUT

= 2.2 µF, and CBIAS = 0.1 µF (unless otherwise noted)

1100

16

TJ

40qC

0qC

25qC

900

85qC

105qC

125qC

800

700

600

500

TJ

25qC

85qC

40qC

0qC

14

Bias Pin Current (PA)

Bias Voltage Dropout (mV)

1000

105qC

125qC

12

10

8

6

4

2

400

0

50

100

150

200 250 300 350

Output Current (mA)

400

450

0

1.5

500

2

2.5

3

3.5

4

Bias Voltage (V)

4.5

5

5.5

IOUT = 0 mA

65

60

55

50

45

40

35

30

25

20

15

10

5

0

1.5

Figure 6-8. IQ(BIAS) vs VBIAS and Temperature

3

TJ

25qC

85qC

40qC

0qC

T

40 qC

0 qC

25 qC

2.8

105qC

125qC

2.6

Input Pin Current (PA)

Bias Pin Current (PA)

Figure 6-7. VBIAS Dropout vs IOUT and Temperature

2.4

2.2

2

1.8

1.6

1.4

1.2

2

2.5

3

3.5

4

Bias Voltage (V)

4.5

5

1

0.5

5.5

1

IOUT = 500 mA

1.5

2

2.5

Input Voltage (V)

3

3.5

IOUT = 0 mA

Figure 6-9. IQ(BIAS) vs VBIAS and Temperature

Figure 6-10. IQ(IN) vs VIN and Temperature

1.2

18

TJ

40qC

0qC

25qC

16

14

85qC

105qC

125qC

1

Output Voltage (V)

Input Pin Current (PA)

85 qC

105 qC

125 qC

12

10

8

6

0.8

0.6

TJ

40 qC

0 qC

25 qC

85 qC

105 qC

125 qC

0.4

4

0.2

2

0

1

1.5

2

2.5

Input Voltage (V)

3

3.5

0

100

200

300

400

500 600 700 800

Output Current (mA)

900 1000 1100

IOUT = 500 mA

Figure 6-11. IQ(IN) vs VIN and Temperature

Figure 6-12. Foldback Output Current Limit vs IOUT and

Temperature

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

9

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

6.6 Typical Characteristics (continued)

at operating temperature TJ = 25°C, VIN = VOUT(NOM) + 0.5 V, VBIAS = VOUT(NOM) + 1.4 V, IOUT = 1 mA, VEN = VIN, CIN = COUT

= 2.2 µF, and CBIAS = 0.1 µF (unless otherwise noted)

3

3.5

TJ

40 qC

0 qC

25 qC

2.5

85 qC

105 qC

125 qC

VIN

VEN

2.5

VBIAS

VOUT

2

Voltage (V)

2

1.5

1

1.5

1

0.5

0.5

0

0

-0.5

0.6

-0.5

0.9

1.2

1.5

1.8

2.1

2.4

Input Voltage (V)

2.7

3

0

3.3

100

200

300

VOUT = 1.0 V, VEN < 0.4 V

700

Figure 6-13. ISHDN vs VIN and Temperature

Figure 6-14. Startup With VEN = VIN

VIN

VEN

VBIAS

VOUT

VIN

VEN

2.5

VBIAS

VOUT

2

Voltage (V)

2

1.5

1

1.5

1

0.5

0.5

0

0

-0.5

-0.5

0

100

200

300

400 500 600

Time (Ps)

700

800

900 1000

0

100

200

300

VOUT = 0.5 V

400 500 600

Time (Ps)

700

5

2.5

VBIAS

VOUT

50

4.5

25

4

Input Voltage (V)

2

1.5

1

0.5

0

-0.5

0

100

200

300

400 500 600

Time (Ps)

900 1000

Figure 6-16. Startup With Separated VEN

3

VIN

VEN

800

VOUT = 0.5 V

Figure 6-15. Startup With VEN and VBIAS Powering Up

Simultaneously

Voltage (V)

900 1000

3

2.5

700

800

900 1000

0

3.5

-25

VIN

-50

VOUT

-75

3

2.5

2

-100

1.5

-125

1

-150

0.5

-175

0

0

100

VOUT = 0.5 V

200

300

400 500 600

Time (Ps)

700

800

-200

900 1000

VOUT = 1.0 V, IOUT = 1 mA

Figure 6-17. Startup With VBIAS Powering Up After VIN and VEN

10

800

VOUT = 0.5 V

3

Voltage (V)

400 500 600

Time (Ps)

AC-coupled Output Voltage (mV)

Input Pin Shutdown Current (PA)

3

Submit Document Feedback

Figure 6-18. VIN Transient

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

6.6 Typical Characteristics (continued)

at operating temperature TJ = 25°C, VIN = VOUT(NOM) + 0.5 V, VBIAS = VOUT(NOM) + 1.4 V, IOUT = 1 mA, VEN = VIN, CIN = COUT

= 2.2 µF, and CBIAS = 0.1 µF (unless otherwise noted)

100

450

0

400

-50

3.5

2.5

-100

VIN

-150

VOUT

-200

2

-250

1.5

-300

3

1

-350

0.5

-400

0

-450

900 1000

100

200

300

400 500 600

Time (Ps)

700

800

-100

350

-200

-300

300

VOUT

IOUT 250

-400

200

-500

150

-600

100

-700

50

-800

0

-900

-50

-1000

0

100

VOUT = 1.0 V, IOUT = 500 mA

450

0

400

-100

350

-200

-300

300

VOUT

IOUT 250

-400

200

-500

150

-600

100

-700

50

-800

0

-900

-50

-1000

300

400 500 600

Time (Ps)

700

800

AC-Coupled Output Voltage (mV)

100

Output Current (mA)

AC-Coupled Output voltage (mV)

500

200

-100

900 1000

1000

-200

VOUT

IOUT

500

-600

250

-800

0

200

VOUT

IOUT

750

-400

500

-600

250

-800

0

-250

1000

100

Power-Supply Rejection Ratio (dB)

1000

800

-250

1000

800

Figure 6-22. IOUT Transient

0

-1000

400

600

Time (Ps)

VOUT = 1.0 V, IOUT = 0 mA to 500 mA

1250

-200

750

-400

-1000

Output Current (mA)

AC-Coupled Output Voltage (mV)

-100

900 1000

0

0

200

400

600

Time (Ps)

800

1250

Figure 6-21. IOUT Transient

200

700

200

VOUT = 1.0 V, IOUT = 1 mA to 250 mA

0

400 500 600

Time (Ps)

Figure 6-20. IOUT Transient

200

100

300

VOUT = 1.0 V, IOUT = 0 mA to 250 mA

Figure 6-19. VIN Transient

0

200

Ouput Current (mA)

0

500

Output Current (mA)

200

0

AC-Coupled Output Voltage (mV)

Input Voltage (V)

4

50

AC-Coupled Output Voltage (mV)

5

4.5

IOUT

10 mA

50 mA

100 mA

200 mA

90

80

70

300 mA

400 mA

500 mA

60

50

40

30

20

10

0

10

VOUT = 1.0 V, IOUT = 1 mA to 500 mA

100

1k

10k

100k

Frequency (Hz)

1M

10M

CIN = 0 μF, VOUT = 1.0 V

Figure 6-23. IOUT Transient

Figure 6-24. VIN PSRR vs Frequency and IOUT

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

6.6 Typical Characteristics (continued)

at operating temperature TJ = 25°C, VIN = VOUT(NOM) + 0.5 V, VBIAS = VOUT(NOM) + 1.4 V, IOUT = 1 mA, VEN = VIN, CIN = COUT

= 2.2 µF, and CBIAS = 0.1 µF (unless otherwise noted)

100

VDO

200 mV

400 mV

600 mV

90

80

800 mV

1000 mV

70

60

50

40

30

20

10

0

10

100

1k

10k

100k

Frequency (Hz)

1M

Power-Supply Rejection Ratio (dB)

Power-Supply Rejection Ratio (dB)

100

90

2.2 PF

70

60

50

40

30

20

10

CIN = 0 μF, VOUT = 1.0 V, IOUT = 500 mA, VDO = VIN – VOUT

1k

10k

100k

Frequency (Hz)

1M

10M

Figure 6-26. VIN PSRR vs Frequency and COUT

100

50

90

2.4 V

3.0 V

3.5 V

80

VBIAS

4.0 V

4.5 V

5.0 V

5.5 V

70

60

50

40

30

20

2

1

0.5

0.2

0.1

0.05

0.02

0.01

0.005

10

10

0

10

100

1k

10k

100k

Frequency (Hz)

1M

IOUT, (PVRMS)

50 mA, (91.2)

300 mA, (85.4)

120 mA, (88.4)

400 mA, (83.7)

200 mA, (86.8)

500 mA, (82.1)

20

10

5

Output Voltage Noise (PV —Hz)

Power-Supply Rejection Ratio (dB)

100

CIN = 0 μF, VOUT = 1.0 V, IOUT = 500 mA

Figure 6-25. VIN PSRR vs Frequency and Dropout

10M

100

1k

1M

10M

Figure 6-28. Output Noise vs Frequency and IOUT

Figure 6-27. VBIAS PSRR vs Frequency and VBIAS

1.65

20

VOUT = 0.5 V, 32.2 PVRMS

VOUT = 1.0 V, 82.2 PVRMS

VOUT = 3.0 V, 193.9 PVRMS

10

1.6

Bias Voltage (UVLO) (V)

5

2

1

0.5

0.2

0.1

0.05

0.02

1.55

1.5

1.45

1.4

1.35

0.01

0.005

10

10k

100k

Frequency (Hz)

VOUT = 1.0 V

CIN = 2.2 μF, VOUT = 1.0 V, IOUT = 500 mA, CBIAS = 0 μF

Output Voltage Noise (PV —Hz)

22 PF

80

0

10

10M

COUT

10 PF

100

1k

10k

100k

Frequency (Hz)

1M

10M

1.3

-40

VBIAS UVLO (Falling)

VBIAS UVLO (Rising)

-20

0

20

40

60

80

Temperature (°C)

100

120

140

IOUT = 500 mA

Figure 6-29. Output Noise vs Frequency and VOUT

12

Figure 6-30. VUVLO(BIAS) Rising and Falling Threshold vs

Temperature

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

6.6 Typical Characteristics (continued)

at operating temperature TJ = 25°C, VIN = VOUT(NOM) + 0.5 V, VBIAS = VOUT(NOM) + 1.4 V, IOUT = 1 mA, VEN = VIN, CIN = COUT

= 2.2 µF, and CBIAS = 0.1 µF (unless otherwise noted)

0.69

0.605

0.68

0.595

0.585

0.66

0.65

VIN UVLO (Falling)

VIN UVLO (Rising)

0.64

0.63

0.62

0.61

Enable Voltage (V)

Input Voltage (UVLO) (V)

0.67

VEN(LO)

VEN(HI)

0.575

0.565

0.555

0.545

0.535

0.6

0.525

0.59

0.58

-40

-20

0

20

40

60

80

Temperature (°C)

100

120

Figure 6-31. VUVLO(IN) Rising and Falling Threshold vs

Temperature

140

0.515

-40

-20

0

20

40

60

80

Temperature (qC)

100

120

140

Figure 6-32. Enable High and Low Threshold vs Temperature

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

13

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

7 Detailed Description

7.1 Overview

The TPS7A11 is a low-input, ultra-low dropout, and low quiescent current linear regulator that is optimized for

excellent transient performance. These characteristics make the device ideal for most battery-powered

applications. The implementation of the BIAS pin on the TPS7A11 vastly improves efficiency of low-voltage

output applications by allowing the use of a pre-regulated, low-voltage input supply that offers sub-band-gap

output voltages. This low-dropout regulator (LDO) offers foldback current limit, shutdown, thermal protection,

high output voltage accuracy of 1.5% over the recommended junction temperature range, and optional active

discharge.

7.2 Functional Block Diagram

Current

Limit

IN

OUT

Thermal

Shutdown

BIAS

+

Bandgap

EN

±

Global

UVLO

Internal

Controller

Active Discharge

P-Version Only

GND

7.3 Feature Description

7.3.1 Excellent Transient Response

The TPS7A11 responds quickly to a transient on the input supply (line transient) or the output current (load

transient) resulting from the device high input impedance and low output impedance across frequency. This

same capability also means that the device has a high power-supply rejection ratio (PSRR) and low internal

noise floor (en). The LDO approximates an ideal power supply with outstanding line and load transient

performance.

The choice of external component values optimizes the small- and large-signal response; see the Input and

Output Capacitor Requirements section for proper capacitor selection.

14

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

7.3.1.1 Global Undervoltage Lockout (UVLO)

The TPS7A11 uses two undervoltage lockout circuits: one on the BIAS pin and one on the IN pin to prevent the

device from turning on before either VBIAS and VIN rise above their lockout voltages. The two UVLO signals are

connected internally through an AND gate, as shown in Figure 7-1, that allows the device to be turned off when

either of these rails are below the lockout voltage.

UVLO(IN)

Global UVLO

UVLO(BIAS)

Figure 7-1. Global UVLO circuit

7.3.2 Active Discharge

The active discharge option has an internal pulldown MOSFET that connects a 120-Ω resistor to ground when

the device is disabled in order to actively discharge the output voltage. The active discharge circuit is activated

by driving the enable pin to logic low to disable the device, or when the device is in thermal shutdown.

The discharge time after disabling the device depends on the output capacitance (COUT) and the load resistance

(RL ) in parallel with the 120-Ω pulldown resistor. Equation 1 calculates this time:

t=

120 · RL

120 + RL

· COUT

(1)

Do not rely on the active discharge circuit for discharging a large amount of output capacitance after the input

supply has collapsed because reverse current can flow from the output to the input. This reverse current flow

can cause damage to the device. Limit reverse current to no more than 5% of the device-rated current.

7.3.3 Enable Pin

The enable pin for the device is active high. The output of the device is turned on when the enable pin voltage is

greater than the EN pin logic high voltage, and the output of the device is turned off when the enable pin voltage

is less than the EN pin logic low voltage. A voltage less than the EN pin logic low voltage on the enable pin

disables all internal circuits.

7.3.4 Sequencing Requirement

The IN, BIAS, and EN pin voltages can be sequenced in any order without causing damage to the device. The

start up is always monotonic regardless of the sequencing order or the ramp rates of the IN, BIAS, and EN pins.

For optimum device performance, VBIAS should be present before enabling the device because the device

internal circuitry is powered by VBIAS. For part numbers with an A following the voltage digits (example:

TPS7A11xxPA), the shutdown current is independent of sequencing. For part numbers without an A following the

voltage digits (example: TPS7A11xxP), the shutdown current into the BIAS input may increase by approximately

2 µA if the BIAS supply was present before the LDO was enabled and then disabled. This behavior can be

avoided with part numbers without an A by applying a logic high enable signal before applying the BIAS supply.

See the Recommended Operating Conditions table for proper voltage ranges of the IN, BIAS, and EN pins.

7.3.5 Internal Foldback Current Limit

The internal foldback current limit circuit is used to protect the LDO against high-load current faults or shorting

events. The foldback mechanism lowers the current limit as the output voltage decreases and limits power

dissipation during short-circuit events, while still allowing for the device to operate at the rated output current;

see Figure 6-12.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

15

�TPS7A11

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

www.ti.com

For example, when VOUT is 90% of VOUT(nom), the current limit is ICL (typical); however, if VOUT is forced to 0 V,

the current limit is ISC (typical). In many LDOs, the foldback current limit can prevent start up into a constantcurrent load or a negatively-biased output. A brick-wall current limit is when there is an abrupt current stop after

the current limit is reached. The foldback mechanism for this device goes into a brick-wall current limit when

VOUT is 90% of VOUT(nom), thus limiting current to ICL (typical). When VOUT is approximately 0 V, current is limited

to ISC (typical) in order to provide normal start up into a variety of loads. Thermal shutdown can be activated

during a current-limit event because of the high power dissipation typically found in these conditions. To provide

proper operation of the current limit, minimize the inductances to the input and load. Continuous operation in

current limit is not recommended.

7.3.6 Thermal Shutdown

The device contains a thermal shutdown protection circuit to disable the device when the thermal junction

temperature (TJ ) of the main pass-FET rises to the thermal shutdown temperature (TSD) for shutdown listed in

the Electrical Characteristics table. Thermal shutdown hysteresis ensures that the LDO resets again (turns on)

when the temperature falls to TSD for reset.

The thermal time constant of the semiconductor die is fairly short, and thus the device may cycle on and off

when thermal shutdown is reached until the power dissipation is reduced.

For reliable operation, limit the junction temperature to a maximum of 125°C. Operation above 125°C causes the

device to exceed the operational specifications. Although the internal protection circuitry of the device is

designed to protect against thermal overload conditions, this circuitry is not intended to replace proper heat

sinking. Continuously running the device into thermal shutdown or above a junction temperature of 125°C

reduces long-term reliability.

A fast start up when TJ > TSD for reset (typical, outside of the specified operation range) causes the device

thermal shutdown to assert at TSD for reset, and prevents the device from turning on until the junction

temperature is reduced below TSD for reset.

16

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

7.4 Device Functional Modes

The device has the following modes of operation:

•

•

•

Normal operation: The device regulates to the nominal output voltage

Dropout operation: The pass element operates as a resistor and the output voltage is set as VIN – VDO

Disabled: The output of the device is disabled and the discharge circuit is activated

Table 7-1 shows the conditions that lead to the different modes of operation.

Table 7-1. Device Functional Mode Comparison

OPERATING MODE

PARAMETER

VIN

VBIAS

VEN

IOUT

TJ

Normal mode

VIN > VOUT (nom) + VDO

and VIN > VIN(min)

VBIAS > VOUT + VDO(BIAS)

VEN > VHI(EN)

IOUT < ICL

TJ < TSD for

shutdown

Dropout mode

VIN(min) < VIN < VOUT

(nom) + VDO(IN)

VBIAS < VOUT + VDO(BIAS)

VEN > VHI(EN)

IOUT < ICL

TJ < TSD for

shutdown

VIN < VUVLO(IN)

VBIAS < VBIAS(UVLO)

VEN < VLO(EN)

—

TJ > TSD for

shutdown

Disabled mode

(any true condition

disables the device)

7.4.1 Normal Mode

The device regulates the output to the nominal output voltage when all normal mode conditions in Table 7-1 are

met.

7.4.2 Dropout Mode

The device is not in regulation, and the output voltage tracks the input voltage minus the voltage drop across the

pass element of the device. In this mode, the PSRR, noise, and transient performance of the device are

significantly degraded.

7.4.3 Disable Mode

In this mode the pass element is turned off, the internal circuits are shut down, and the output voltage is actively

discharged to ground by an internal resistor.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

17

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

8 Application and Implementation

Note

Information in the following applications sections is not part of the TI component specification, and TI

does not warrant its accuracy or completeness. TI’s customers are responsible for determining

suitability of components for their purposes, as well as validating and testing their design

implementation to confirm system functionality.

8.1 Application Information

Successfully implementing an LDO in an application depends on the application requirements. This section

discusses key device features and how to best implement them to achieve a reliable design.

8.1.1 Recommended Capacitor Types

The device is designed to be stable using low equivalent series resistance (ESR) ceramic capacitors at the input,

output, and bias pins. Multilayer ceramic capacitors are the industry standard for these types of applications, but

must be used with good judgment. Ceramic capacitors that use X7R-, X5R-, and COG-rated dielectric materials

provide relatively good capacitive stability across temperature. Avoid Y5V-rated capacitors because of large

variations in capacitance. Regardless of the ceramic capacitor type selected, ceramic capacitance varies with

operating voltage and temperature. As a rule of thumb, assume that effective capacitance decreases by as much

as 50%. The input, output, and bias capacitors recommended in the Recommended Operating Conditions table

account for an effective capacitance of approximately 50% of the nominal value.

8.1.2 Input and Output Capacitor Requirements

A minimum input ceramic capacitor is required for stability. A minimum output ceramic capacitor is also required

for stability, refer to the Recommended Operating Conditions table for the minimum capacitors values.

The input capacitor counteracts reactive input sources and improves transient response, input ripple, and PSRR.

A higher-value input capacitor may be necessary if large, fast rise-time load or line transients are anticipated, or

if the device is located several inches from the input power source. Dynamic performance of the device is

improved with the use of an output capacitor larger than the minimum value specified in the Recommended

Operating Conditions table.

Although a bias capacitor is not required, connect a 0.1-µF ceramic capacitor from BIAS to GND for best analog

design practice. This capacitor counteracts reactive bias sources if the source impedance is not sufficiently low.

Place the input, output, and bias capacitors as close as possible to the device to minimize trace parasitics.

8.1.3 Load Transient Response

The load-step transient response is the output voltage response by the LDO to a step in load current while

output voltage regulation is maintained. See Figure 6-20 to Figure 6-23 for typical load transient response. There

are two key transitions during a load transient response: the transition from a light to a heavy load, and the

transition from a heavy to a light load. The regions in Figure 8-1 are broken down as described in this section.

Regions A, E, and H are where the output voltage is in steady-state operation.

tAt

tCt

B

tDt

tEt

tGt

tHt

F

Figure 8-1. Load Transient Waveform

18

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

During transitions from a light load to a heavy load, the:

•

•

Initial voltage dip is a result of the depletion of the output capacitor charge and parasitic impedance to the

output capacitor (region B)

Recovery from the dip results from the LDO increasing the sourcing current, and leads to output voltage

regulation (region C)

During transitions from a heavy load to a light load, the:

•

•

Initial voltage rise results from the LDO sourcing a large current, and leads to an increase in the output

capacitor charge (region F)

Recovery from the rise results from the LDO decreasing its sourcing current in combination with the load

discharging the output capacitor (region G)

A larger output capacitance reduces the peaks during a load transient but slows down the response time of the

device. A larger dc load also reduces the peaks because the amplitude of the transition is lowered and a higher

current discharge path is provided for the output capacitor.

8.1.4 Dropout Voltage

Generally, the dropout voltage often refers to the minimum voltage difference between the input and output

voltage (VDO = VIN – VOUT) that is required for regulation. When VIN – VOUT drops below the required VDO for the

given load current, the device functions as a resistive switch and does not regulate output voltage. Dropout

voltage is linearly proportional to the output current because the device is operating as a resistive switch, see

Figure 6-4 and Figure 6-5.

Dropout voltage is also affected by the drive strength for the gate of the pass element, which is nonlinear with

respect to VBIAS on this device because of the inherited nonlinearity of the pass element gate capacitance, see

Figure 6-7.

8.1.5 Behavior During Transition From Dropout Into Regulation

Some applications may have transients that place this device into dropout, especially when this device can be

powered from a battery with relatively high ESR. The load transient saturates the output stage of the error

amplifier when the pass element is driven fully on, making the pass element function like a resistor from VIN to

VOUT. The error amplifier response time to this load transient is limited because the error amplifier must first

recover from saturation and then places the pass element back into active mode. During this time, VOUT

overshoots because the pass element is functioning as a resistor from VIN to VOUT.

When VIN ramps up slowly for start-up, the slow ramp-up voltage may place the device in dropout. As with many

other LDOs, the output can overshoot on recovery from this condition. However, this condition is easily avoided

through the use of the enable signal.

If operating under these conditions, apply a higher dc load or increase the output capacitance to reduce the

overshoot. These solutions provide a path to dissipate the excess charge.

8.1.6 Undervoltage Lockout Circuit Operation

The VIN UVLO circuit makes sure that the device remains disabled before the input supply reaches the minimum

operational voltage range. The VIN UVLO circuit also makes sure that the device shuts down when the input

supply collapses. Similarly, the VBIAS UVLO circuit makes sure that the device stays disabled before the bias

supply reaches the minimum operational voltage range. The VBIAS UVLO circuit also makes sure that the device

shuts down when the bias supply collapses.

Figure 8-2 depicts the UVLO circuit response to various input or bias voltage events. The diagram can be

separated into the following parts:

•

•

•

•

Region A: The device does not start until the input or bias voltage reaches the UVLO rising threshold

Region B: Normal operation, regulating device

Region C: Brownout event above the UVLO falling threshold (UVLO rising threshold – UVLO hystersis). The

output may fall out of regulation but the device is still enabled.

Region D: Normal operation, regulating device

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

19

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

•

•

•

Region E: Brownout event below the UVLO falling threshold. The device is disabled in most cases and the

output falls as a result of the load and active discharge circuit. The device is re-enabled when the UVLO

rising threshold is reached and a normal start-up follows.

Region F: Normal operation followed by the input or bias falling to the UVLO falling threshold

Region G: The device is disabled when the input or bias voltages fall below the UVLO falling threshold to 0 V.

The output falls as a result of the load and active discharge circuit.

UVLO Rising Threshold

UVLO Hysteresis

VIN / VBIAS

C

VOUT

tAt

tBt

tDt

tEt

tFt

tGt

Figure 8-2. Typical VIN or VBIAS UVLO Circuit Operation

8.1.7 Power Dissipation (PD)

Circuit reliability demands that proper consideration be given to device power dissipation, location of the circuit

on the printed circuit board (PCB), and correct sizing of the thermal plane. The PCB area around the regulator

must be as free as possible of other heat-generating devices that cause added thermal stresses.

Equation 2 calculates the maximum allowable power dissipation for the device in a given package:

PD-MAX = [(TJ – TA) / RθJA]

(2)

Equation 3 represents the actual power being dissipated in the device:

PD = (IGND + IOUT) × (VIN – VOUT)

(3)

Power dissipation can be minimized, and thus greater efficiency achieved, by proper selection of the system

voltage rails. Proper selection allows the minimum input-to-output voltage differential to be obtained. The low

dropout of the TPS7A11 allows for maximum efficiency across a wide range of output voltages.

The main heat conduction path for the device depends on the ambient temperature and the thermal resistance

across the various interfaces between the die junction and ambient air.

The maximum power dissipation determines the maximum allowable junction temperature (TJ) for the device.

According to Equation 4, maximum power dissipation and junction temperature are most often related by the

junction-to-ambient thermal resistance (RθJA) of the combined PCB and device package and the temperature of

the ambient air (TA). The equation is rearranged in Equation 5 for output current.

TJ = TA + (RθJA × PD)

(4)

IOUT = (TJ – TA) / [RθJA × (VIN – VOUT)]

(5)

Unfortunately, this thermal resistance (RθJA) is highly dependent on the heat-spreading capability built into the

particular PCB design, and therefore varies according to the total copper area, copper weight, and location of the

planes. The RθJA recorded in the Electrical Characteristics table is determined by the JEDEC standard, PCB,

and copper-spreading area, and is only used as a relative measure of package thermal performance. For a welldesigned thermal layout, RθJA is actually the sum of the DRV package junction-to-case (bottom) thermal

resistance (RθJC(bot)) plus the thermal resistance contribution by the PCB copper.

20

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

8.1.8 Estimating Junction Temperature

The JEDEC standard now recommends the use of psi (Ψ) thermal metrics to estimate the junction temperatures

of the LDO when in-circuit on a typical PCB board application. These metrics are not strictly speaking thermal

resistances, but rather offer practical and relative means of estimating junction temperatures. These psi metrics

are determined to be significantly independent of the copper-spreading area. The key thermal metrics (ΨJT and

ΨJB) are used in accordance with Equation 6 and are given in the Electrical Characteristics table.

ΨJT : TJ = TT + ΨJT × PD and ΨJB : TJ = TB + ΨJB × PD

(6)

where:

•

•

•

PD is the power dissipated as explained in Equation 3

TT is the temperature at the center-top of the device package

TB is the PCB surface temperature measured 1 mm from the device package and centered on the package

edge

8.1.9 Recommended Area for Continuous Operation

The operational area of an LDO is limited by the dropout voltage, output current, junction temperature, and input

voltage. The recommended area for continuous operation for a linear regulator is shown in Figure 8-3 and can

be separated into the following regions:

•

•

•

Output Current (A)

•

Dropout voltage limits the minimum differential voltage between the input and the output (VIN – VOUT) at a

given output current level; see the Dropout Voltage section for more details.

The rated output current limits the maximum recommended output current level. Exceeding this rating causes

the device to fall out of specification.

The rated junction temperature limits the maximum junction temperature of the device. Exceeding this rating

causes the device to fall out of specification and reduces long-term reliability.

– Equation 5 provides the shape of the slope. The slope is nonlinear because the maximum rated junction

temperature of the LDO is controlled by the power dissipation across the LDO, thus when VIN – VOUT

increases the output current must decrease.

The rated input voltage range governs both the minimum and maximum of VIN – VOUT.

Output Current Limited

by Dropout

Rated Output

Current

Output Current Limited

by Thermals

Limited by

Maximum VIN

Limited by

Minimum VIN

VIN ± VOUT (V)

Figure 8-3. Continuous Operation Diagram With Description of Regions

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

21

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

8.2 Typical Application

2.4 V ~ 5.5 V

IN

OUT

Low Iq

DC/DC Converter

Rechargeable

Battery

CBIAS

1.2 V

CIN

BIAS

IN

1.0 V

OUT

VOUT

COUT

TPS7A11

EN

GND

GND

Figure 8-4. High Efficiency Supply From a Rechargeable Battery

8.2.1 Design Requirements

Table 8-1 lists the parameters for this design example.

Table 8-1. Design Parameters

DESIGN PARAMETER

EXAMPLE VALUE

VIN

1.2 V

VBIAS

2.4 V (min)

VOUT

1.0 V

IOUT

150 mA (typical), 500 mA (peak)

8.2.2 Detailed Design Procedures

This design example is powered by a rechargeable battery that can be a building block in many portable

applications. Noise-sensitive portable electronics require an efficient small-size solution for their power supply.

Traditional LDOs are known for their low efficiency in contrast to the low-input, low-output voltage (LILO) LDOs

such as the TPS7A11. The use of a bias rail in the TPS7A11 allows the device to operate at a lower input

voltage, thus reducing the power dissipation across the die and maximizing device efficiency. Equation 7

calculates the efficiency for this design.

Efficiency = η = POUT/PIN ×100 % = (VOUT × IOUT) /(VIN × IIN + VBIAS × IBIAS) × 100 %

(7)

Equation 7 reduces to Equation 8 because the design example load current is much greater than the quiescent

current of the bias rail.

Efficiency = η = (VOUT × IOUT) / (VIN × IIN) × 100%

22

Submit Document Feedback

(8)

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

8.2.3 Application Curve

Figure 8-5 shows a plot of the calculated efficiency.

100

Efficiency ( )

80

60

40

20

0

0.001

0.01

0.1

1

10

Output Current (mA)

100

1000

VIN = VEN = 1.2 V, CIN = 2.2 µF, VOUT = 1.0 V, COUT = 2.2 µF, VBIAS = 2.4 V, CBIAS = 0.1 µF

Figure 8-5. TPS7A11 Output Efficiency at 1.2 VIN and 1.0 VOUT

9 Power Supply Recommendations

This device is designed to operate from an input supply voltage range of 0.75 V to 3.3 V and a bias supply

voltage range of 1.7 V to 5.5 V. The input and bias supplies must be well regulated and free of spurious noise. To

make sure that the output voltage is well regulated and dynamic performance is optimum, the input supply must

be at least VOUT(nom) + 0.5 V and VBIAS = VOUT(nom) + VDO(BIAS).

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

23

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

10 Layout

10.1 Layout Guidelines

For correct printed circuit board (PCB) layout, follow these guidelines:

•

•

•

Place input, output, and bias capacitors as close to the device as possible

Use copper planes for device connections to optimize thermal performance

Place thermal vias around the device to distribute heat

10.2 Layout Examples

OUT

IN

CIN

COUT

A1

GND

A3

B2

C1

C3

CBIAS

EN

BIAS

Figure 10-1. Recommended Layout for YKA Package

Ground Plane

To Bias Supply

4

BIAS

5

GND

EN

3

NC

2

To Enable

Signal

Thermal Pad

CBIAS

COUT

CIN

6

IN

OUT

1

To Load

To Input Supply

Ground Plane

Figure 10-2. Recommended Layout for DRV Package

24

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

11 Device and Documentation Support

11.1 Device Support

11.1.1 Development Support

11.1.1.1 Evaluation Module

An evaluation module (EVM) is available to assist in the initial circuit performance evaluation using the

TPS7A11. The TPS720xxDRVEVM evaluation module (and related user guide) can be requested at the Texas

Instruments website through the product folders or purchased directly from the TI eStore.

11.1.2 Spice Model

Spice models for this device are available through the for the TPS7A11 product folder under the Tool and

Software tab.

11.1.3 Device Nomenclature

Table 11-1. Device Nomenclature (1) (2)

(1)

(2)

PRODUCT

VOUT

TPS7A11xx(x)(P)(A)yyyz

xx(x) is the nominal output voltage. For output voltages with a resolution of 50 mV, two digits are used in

the ordering number; otherwise, three digits are used (for example, 28 = 2.8 V; 125 = 1.25 V).

(P), when present, indicates the active discharge option.

(A), when present, indicates the BIAS shutdown current is independent of sequencing. See the

Sequencing Requirement section.

yyy is the package designator.

z is the package quantity. R is for reel (3000 pieces), T is for tape (250 pieces).

() indicates optional placeholders.

For the most current package and ordering information see the Package Option Addendum at the end of this document, or visit the

device product folder on www.ti.com.

Output voltages from 0.5 V to 3.0 V in 50-mV increments are available. Contact the factory for details and availability.

11.2 Documentation Support

11.2.1 Related Documentation

For related documentation see the following:

• Texas Instruments, TPS720xxDRVEVM Evaluation Module user's guide

• Texas Instruments, Using New Thermal Metrics application report

• Texas Instruments, AN-1112 DSBGA Wafer Level Chip Scale Package application report

• Texas Instruments, TIDA-01566 Light Load Efficient, Low Noise Power Supply Reference Design for

Wearables and IoT design guide

11.3 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. Click on

Subscribe to updates to register and receive a weekly digest of any product information that has changed. For

change details, review the revision history included in any revised document.

11.4 Support Resources

TI E2E™ support forums are an engineer's go-to source for fast, verified answers and design help — straight

from the experts. Search existing answers or ask your own question to get the quick design help you need.

Linked content is provided "AS IS" by the respective contributors. They do not constitute TI specifications and do

not necessarily reflect TI's views; see TI's Terms of Use.

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

25

�TPS7A11

www.ti.com

SBVS316B – SEPTEMBER 2018 – REVISED DECEMBER 2020

11.5 Trademarks

TI E2E™ is a trademark of Texas Instruments.

All trademarks are the property of their respective owners.

11.6 Electrostatic Discharge Caution

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled

with appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may

be more susceptible to damage because very small parametric changes could cause the device not to meet its published

specifications.

11.7 Glossary

TI Glossary

This glossary lists and explains terms, acronyms, and definitions.

Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

26

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS7A11

�PACKAGE OPTION ADDENDUM

www.ti.com

30-Sep-2021

PACKAGING INFORMATION

Orderable Device

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

TPS7A1105PYKAR

ACTIVE

DSBGA

YKA

5

12000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

G

TPS7A1106PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1R6H

TPS7A1106PDRVT

ACTIVE

WSON

DRV

6

250

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1R6H

TPS7A1106PYKAR

ACTIVE

DSBGA

YKA

5

12000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

H

TPS7A11075PYKAR

ACTIVE

DSBGA

YKA

5

12000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

I

TPS7A1108PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1R7H

TPS7A1108PDRVT

ACTIVE

WSON

DRV

6

250

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1R7H

TPS7A1109PYKAR

ACTIVE

DSBGA

YKA

5

12000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

J

TPS7A11105PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1R9H

TPS7A11105PDRVT

ACTIVE

WSON

DRV

6

250

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1R9H

TPS7A11105PYKAR

ACTIVE

DSBGA

YKA

5

12000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

K

TPS7A1110PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1R8H

TPS7A1110PDRVT

ACTIVE

WSON

DRV

6

250

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1R8H

TPS7A1110PYKAR

ACTIVE

DSBGA

YKA

5

12000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

L

TPS7A1111PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1RAH

TPS7A1111PDRVT

ACTIVE

WSON

DRV

6

250

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1RAH

TPS7A1111PYKAR

ACTIVE

DSBGA

YKA

5

12000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

3

TPS7A1112PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1RBH

TPS7A1112PDRVT

ACTIVE

WSON

DRV

6

250

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1RBH

TPS7A1112PYKAR

ACTIVE

DSBGA

YKA

5

12000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

U

Addendum-Page 1

Samples

�PACKAGE OPTION ADDENDUM

www.ti.com

Orderable Device

30-Sep-2021

Status

(1)

Package Type Package Pins Package

Drawing

Qty

Eco Plan

(2)

Lead finish/

Ball material

MSL Peak Temp

Op Temp (°C)

Device Marking

(3)

(4/5)

(6)

TPS7A1115PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1RCH

TPS7A1115PDRVT

ACTIVE

WSON

DRV

6

250

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1RCH

TPS7A1118PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1RDH

TPS7A1118PDRVT

ACTIVE

WSON

DRV

6

250

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1RDH

TPS7A1118PYKAR

ACTIVE

DSBGA

YKA

5

12000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

M

TPS7A1119PYKAR

ACTIVE

DSBGA

YKA

5

12000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

D

TPS7A1125PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1REH

TPS7A1125PDRVT

ACTIVE

WSON

DRV

6

250

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1REH

TPS7A1128PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1RFH

TPS7A1128PDRVT

ACTIVE

WSON

DRV

6

250

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1RFH

TPS7A1128PYKAR

ACTIVE

DSBGA

YKA

5

12000

RoHS & Green

SNAGCU

Level-1-260C-UNLIM

-40 to 125

N

TPS7A1130PDRVR

ACTIVE

WSON

DRV

6

3000

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1RGH

TPS7A1130PDRVT

ACTIVE

WSON

DRV

6

250

RoHS & Green

NIPDAU

Level-1-260C-UNLIM

-40 to 125

1RGH

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of