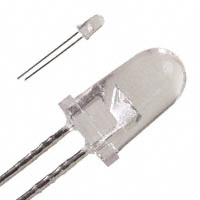

SLI-580x/SLA-580x/SLA580x Series

Data Sheet

■Features

• Viewing angle 2θ 1/2 : 10°

■Outline

Color

Type

U

D

Y

M

E

B

■Dimensions

■Recommended Solder Pattern

1.0 ±0.1 2.0

2.5 or 5.0

Tolerance : ±0.2

(unit : mm)

(unit : mm)

■Specifications

Absolute Maximum Ratings (Ta=25ºC)

Emitting

Part No.

Power Forward

Peak Forward

Color

Dissipation

Current Current Voltage

PD(mW) IF(mA) IFP(mA) VR(V)

SLI-580DT

Typ.

Topr(ºC)

Tstg(ºC)

(V)

IF

Max.

AlGaInP

(mA)

(μA)

Orange

Yellowish green

125

50

200*2

9

-30~+85

-40~+100

1.9

100

75

25

60*1

4

Power Forward

Peak Forward

-25~+85

-30~+100

SLA580ENT

IF

9

2.3

4

Typ.

IF

(mA) (mcd) (mcd) (mA)

2000

5000

605

587

10

Min.

20

563

1350

200

20

470

Forward Voltage VF Reverse Current IR

Dominant Wavelength λD Luminous Intensity IV

Operating Temp. Storage Temp.

Chip Structure

Color

InGaN

Luminous Intensity IV

Electrical and Optical Characteristics (Ta=25ºC)

Reverse

Dissipation

Current Current Voltage

PD(mW) IF(mA) IFP(mA) VR(V)

SLA580BNT

(V)

20

Absolute Maximum Ratings (Ta=25ºC)

Emitting

Part No.

Typ.

(nm)

620

Yellow

GaP

Peak Wavelength λp

VR

Red

SLI-580YT

SLA-580MT

Forward Voltage VF Reverse Current IR

Operating Temp. Storage Temp.

Chip Structure

SLI-580UT

Electrical and Optical Characteristics (Ta=25ºC)

Reverse

GREEN

BLUE

120

30

100*2

5

Topr(ºC)

Tstg(ºC)

-20~+80 -30~+100

Typ.

IF

Max.

VR

Typ.

(V)

(mA)

(μA)

(V)

(nm)

3.3

20

100

5

527

470

IF

Min.

Typ.

IF

(mA) (mcd) (mcd) (mA)

20

6100

27000

20

1350 4000

*1 : Duty1/5, 200Hz,*2:Duty1/10, 1kHz

________________________________________________________

www.rohm.com

1/10

©2022 ROHM Co., Ltd. All rights reserved

2022.2 - Rev.007

�

[SLI-580x/SLA-580x/SLA580x series]

[Data Sheet]

■Electrical Characteristics Curves

Reference

Fig.1 Forward Current

- Forward Voltages

Fig.2 Luminous Intensity Atmosphere Temperature

100

1.6

RELATIVE LUMINOUS INTENSITY

FORWARD CURRENT : IF [mA]

Ta=25ºC

10

1

SLI-580UT

SLI-580DT

SLI-580YT

0.1

1.6

1.7

1.8

1.9

2.0

2.1

1.0

0.5

0

20

30

40

FORWARD CURRENT : IF [mA]

50

MAXIMUM FORWARD CURRENT : [mA]

RELATIVE LUMINOUS INTENSITY

Ta=25ºC

1.5

10

0.8

SLI-580UT

SLI-580DT

SLI-580YT

0.6

-20

0

20

40

60

80

100

Fig.4 Derating

2.5

1

1.0

ATMOSPHERE TEMPERATURE : Ta [ºC]

Fig.3 Luminous Intensity - Forward Current

2.0

1.2

0.4

-40

2.2

FORWARD VOLTAGE : VF [V]

SLI-580UT

SLI-580DT

SLI-580YT

IF=20mA

1.4

50

40

30

20

SLI-580UT

SLI-580DT

SLI-580YT

10

0

-40

-20

0

20

40

60

80

100

AMBIENT TEMPERATURE : Ta [ºC]

________________________________________________________

www.rohm.com

2/10

©2022 ROHM Co., Ltd. All rights reserved

2022.2 - Rev.007

�[SLI-580x/SLA-580x/SLA580x series]

[Data Sheet]

■Electrical Characteristics Curves

Reference

Fig.1 Forward Current

- Forward Voltages

Fig.2 Luminous Intensity Atmosphere Temperature

RELATIVE LUMINOUS INTENSITY

1.4

FORWARD CURRENT : IF [mA]

Ta=25ºC

SLA580ENT

SLA580BNT

IF=20mA

1.2

1.0

0.8

SLA580ENT

SLA580BNT

0.6

0.4

-40

Fig.3 Luminous Intensity - Forward Current

1

0.5

SLA580ENT

SLA580BNT

0

FORWARD CURRENT : IF [mA]

30

MAXIMUM FORWARD CURRENT : [mA]

RELATIVE LUMINOUS INTENSITY

Ta=25ºC

20

20

40

60

80

100

Fig.4 Derating

1.5

10

0

ATMOSPHERE TEMPERATURE : Ta [ºC]

FORWARD VOLTAGE : VF [V]

0

-20

40

30

20

10

SLA580ENT

SLA580BNT

0

-40

-20

0

20

40

60

80

100

AMBIENT TEMPERATURE : Ta [ºC]

________________________________________________________

www.rohm.com

3/10

©2022 ROHM Co., Ltd. All rights reserved

2022.2 - Rev.007

�

[SLI-580x/SLA-580x/SLA580x series]

[Data Sheet]

■Electrical Characteristics Curves

Reference

Fig.1 Forward Current

- Forward Voltages

Fig.2 Luminous Intensity Atmosphere Temperature

1.4

RELATIVE LUMINOUS INTENSITY

FORWARD CURRENT : IF [mA]

50

Ta=25ºC

20

10

5.0

IF=20mA

1.2

1.0

0.8

0.6

SLA-580MT

SLA-580MT

2.0

1.0

1.5

2.0

2.5

0.4

-40

3.0

FORWARD VOLTAGE : VF [V]

1.0

0.8

0.6

0.4

0.2

SLA-580MT

0

15

20

FORWARD CURRENT : IF [mA]

25

MAXIMUM FORWARD CURRENT : [mA]

RELATIVE LUMINOUS INTENSITY

Ta=25ºC

10

20

40

60

80

100

Fig.4 Derating

1.2

5

0

ATMOSPHERE TEMPERATURE : Ta [ºC]

Fig.3 Luminous Intensity - Forward Current

1

-20

40

30

20

10

SLA-580MT

0

-40

-20

0

20

40

60

80

100

AMBIENT TEMPERATURE : Ta [ºC]

________________________________________________________

www.rohm.com

4/10

©2022 ROHM Co., Ltd. All rights reserved

2022.2 - Rev.007

�

[SLI-580x/SLA-580x/SLA580x series]

[Data Sheet]

■Viewing Angle

Reference

SCANNING ANGLE (deg)

SLI-580x series

RELATIVE INTENSITY (%)

SCANNING ANGLE (deg)

20

10

0

30

10

20

30

40

50

60

60

70

70

80

90

100

SLA580ENT

SLA580BNT

40

50

80

50

0

50

RELATIVE INTENSITY (%)

90

100

________________________________________________________

www.rohm.com

5/10

©2022 ROHM Co., Ltd. All rights reserved

2022.2 - Rev.007

�

[SLI-580x/SLA-580x/SLA580x series]

[Data Sheet]

■Rank Reference of Brightness*

*Measurement tolerance:±10%

Red(U)

Rank

Iv (mcd)

SLI-580UT

(Ta=25ºC, IF=20mA)

XE

XF

XG

XH

XJ

XK

XL

47~68 68~100 100~150 150~220 220~330 330~470 470~680

XM

XN

XP

XQ

XR

Orange(D)

Rank

Iv (mcd)

SLI-580DT

XM

XN

XP

XQ

XR

XM

XN

XP

XQ

XR

XS

680~1000 1000~1500 1500~2200 2200~ 3300 3300~4700 4700~6800

XT

6800~10000

(Ta=25ºC, IF=20mA)

XE

XF

XG

XH

XJ

XK

XL

47~68 68~100 100~150 150~220 220~330 330~470 470~680

XM

XN

XP

XQ

XR

XS

680~1000 1000~1500 1500~2200 2200~ 3300 3300~4700 4700~6800

Green(E)

XT

6800~10000

(Ta=25ºC, IF=20mA)

XM

XN

XP

XQ

XR

XS

XT

610~1100 900~1650 1350~2400 2000~ 3600 3000~5200 4200~7500

Blue(B)

Rank

XH

XJ

XK

XL

Iv (mcd)

135~240 200~360 300~520 420~750

SLA580BNT

XT

6800~10000

(Ta=25ºC, IF=20mA)

XE

XF

XG

XH

XJ

XK

XL

47~68 68~100 100~150 150~220 220~330 330~470 470~680

Rank

XH

XJ

XK

XL

Iv (mcd)

135~240 200~360 300~520 420~750

SLA580ENT

XS

680~1000 1000~1500 1500~2200 2200~ 3300 3300~4700 4700~6800

Yellowish Green(M)

Rank

Iv (mcd)

SLA-580MT

XT

6800~10000

(Ta=25ºC, IF=20mA)

XE

XF

XG

XH

XJ

XK

XL

47~68 68~100 100~150 150~220 220~330 330~470 470~680

Yellow (Y)

Rank

Iv (mcd)

SLI-580YT

XS

680~1000 1000~1500 1500~2200 2200~ 3300 3300~4700 4700~6800

XU

XV

XW

6100~11000 9000~16500 13500~24000 20000~36000

(Ta=25ºC, IF=20mA)

XM

XN

XP

XQ

XR

XS

610~1100 900~1650 1350~2400 2000~ 3600 3000~5200 4200~7500

XT

XU

6100~11000 9000~16500

________________________________________________________

www.rohm.com

6/10

©2022 ROHM Co., Ltd. All rights reserved

2022.2 - Rev.007

�

[SLI-580x/SLA-580x/SLA580x series]

[Data Sheet]

■Part No. Construction

*"-"will be taken out for emitting color

Special Code will be applied for

Chromaticity rank

Rank sign

B/E series.

Emitting color B/E series.

(for white LED)

(Brightness Rank)*

S

L

Series name

I

-

5

8

0

Package type

U

T

Emitting Color

T

Resin Color

3

1-Die Circular Type High Brightness LED Lamps

V

Red

R DiffusedColored

SLI

1-Die Circular Type Low Current High Brightness LED Lamps

U

Red

U

SLR

1-Die Circular Type LED Lamps

U2

Red

Y

DiffusedColored

SLD

1-Die Oval Type High Brightness LED Lamps

D

Orange

G

DiffusedColored

Y

Yellow

C

Y2

Yellow

RC

P

Green

E

Green

B

Blue

XS

Taping Specification

SLA

M Yellowish green

2

DiffusedColored

3F 1-Element straight bulk

T□□ See Taping specifications

Transparent Colored

T Transparent Coloreless

*Concerning the Brightness rank.

*Please refer to the rank chart above for

luminous intensity classification.

*Part name is individual for each rank.

*When shipped as sample,the part name will

be a representative part name.

General products are free of ranks.

Please contact sales if rank appointment

is needed.

________________________________________________________

www.rohm.com

7/10

©2022 ROHM Co., Ltd. All rights reserved

2022.2 - Rev.007

�[SLI-580x/SLA-580x/SLA580x series]

[Data Sheet]

■ATTENTION POINTS IN HANDLING

Visual light emitting diode does not contain reinforcement materials such as glass fillers.

Therefore if sudden thermal and mechanical shock are given, destruction or inferiority of luminous

intensity may occur. Please take care of the handling.

■FIXATION METHOD

1.ATTENTION POINTS

(1) Please do not give excessive heat over storage temperature to resin.

In case that the product has to be heated in oven for the glue fixing of surface mount parts,

this LED should be mounted after the glue fixing.

(2) Please avoid stress to resin at high temperature.

2. TERMINATION PROCESSING

(1) In case of termination processing, please fix the

termination

(2) Processing position, and process the reverse side

of LED body.

If stress is given during processing, It may cause

non-lighting failure.

(3) Please process before soldering.

<Good>

<No good>

To be fixed

To be fixed

3. ASSEMBLY ON PC BOARD

(1) In case of soldering on PCB, If the operation is done with stress, it may cause non-lighting

failure during soldering or using. Please design the through-holes of PCB suitable for lead pins

space or lead pins space after forming to avoid the physical stress on resin.

<Good>

<Good>

<No good>

<2 lead pins type>

<3 lead pins type>

(2) Using spacer between LED’s body and PCB is recommended.

In case of direct mount on PCB(SLR/SLI-343 series), please take care about clinch of LED pins

to avoid the remained stress and solder heat stress.

Enough evaluation is requested before deciding assembly and soldering conditions.

Please consult with us if any problems in the evaluation stage.

<3 lead pin type>

<2 lead pin type>

Min.15°

Die bonding side

Min.45°

Min.15°

Min.45

Min.45°

Die bonding side

________________________________________________________

www.rohm.com

8/10

©2022 ROHM Co., Ltd. All rights reserved

2022.2 - Rev.007

�

[SLI-580x/SLA-580x/SLA580x series]

[Data Sheet]

4.SOLDERING(Sn-3Ag-0.5Cu)

(1) Please make soldering rapidly under the following temperature and time conditions.

(2) Please avoid stress to LED lamp during soldering.

(3) In case of double peak flow soldering, the temperature gap during 1st and 2nd soldering to be

less than 100 degree C.

<Recommendable soldering conditions>

SOLDERINGTEMP OPERATION TIME

ARTIICLE

Pre-heat

Max. 100℃ 60sec Max.

Soldering Dip

Remarks

-

In case of double peak flow soldering, the operation

Soldering Bath

Soldering Iron

Max. 265℃

5sec Max.

Max. 400℃

3sec Max.

time is counted from the beginning of 1st peak

to the end of 2nd peak.

The iron should not touch the LED’s body.

5.CLEANING

In case of cleaning, some solvents may cause damage of resin or cause non-lighting failure,

so please check the solvent before actual use.

The recommendable cleaning solvent is alcoholic one such as isopropyl alcohol.

<RECOMMENDABLE CLEANING CONDITIONS>

METHOD

CONDITIONS

Temperature of solvent :Max. 45℃

Cleaning by solvent

Immersion time :Max. 3min

Ultrasonic out :Max. 15W/Liter

Cleaning by solvent

Cleaning time :Max. 3min

6.RECOMMENDABLE ROUND PATTERN

Round pattern depends on the material PCB, density and circuit arrangement.

Our recommendation is as follow :

±0.1

1.0

2.5

or

5.0

±0.1

2.0

1.0

<3 lead pin type/2.0mm pitch>

±0.1

2.0

2.5

2.5

1.0

1.5

2.0

*Unit : mm

*Lead types : □0.4mm

□0.5mm

2.0

φ2.0

■ATTENTION ON STORAGING

Storage in dry box is most desirable, but if it is not possible, we recommend following conditions.

<RECOMMENDABLE STORAGE CONDITIONS>

Temperature Humidity

ARTICLE

Expiration Date

CONDITIONS

5~30℃ Max.60%RH Within 1 year

Poor storage conditions may cause some failure as bellow.

(1) Lead pins may corrode if it is stored in the environment of high temperature and humidity

and lead to defective soldering.

(2) In case of soldering after LED’s body absorb moisture highly, destruction or inferiority of

luminous intensity may occur.

________________________________________________________

www.rohm.com

9/10

©2022 ROHM Co., Ltd. All rights reserved

2022.2 - Rev.007

�[SLI-580x/SLA-580x/SLA580x series]

[Data Sheet]

■APPLICATION METHOD

1.Precaution for Drive System and Off Mode

・Design the circuit without the electric load exceeding the ABSOLUTE MAXIMUM RATING that

applies on the products.

・If drive by constant voltage, it may cause current deviation of the LED and result in deviation of

luminous intensity, so we recommend to drive by constant current. (Deviation of VF Value will

cause deviation of current in LED.)

・Furthermore, for off mode, please do not apply voltage neither forward nor reverse. Especially,

for the products with the Ag-paste used in the die bonding, there’s high possibility to cause electro

migration and result in function failure.

2. Operation Life Span

There’s possibility for intensity of light drop according to working conditions and environments

(applied current, surrounding temperature and humidity, corrosive gases ), please call our Sales

staffs for inquiries about the concerned application below.

(1) Longtime intensity of light life

(2) On mode all the time

3. Usage

The Product is LED. We are not responsible for the usage as the diode such as Protection Chip,

Rectifier, Switching and so on.

■OTHERS

1. Surrounding Gas

Notice that if it is stored under the condition of acid gas (chlorine gas, sulfured gas) or alkali gas

(ammonia), it may result in low soldering ability (caused by the change in quality of the plating

surface ) or optical characteristics changes (light intensity, chrominance) and change in quality of

die bonding (Ag-paste) materials. All of the above will cause function failure of the products.

Therefore, please pay attention to the storage environment for mounted product (concern the

generated gas of the surrounding parts of the products and the atmospheric environment).

2. Electrostatic Damage

The product is part of semiconductor and electrostatic sensitive, there’s high possibility to be

damaged by the electrostatic discharge.

Please take appropriate measures to avoid the static electricity from human body and earthing

setting of production equipment. The resistance values of electrostatic discharge (actual values)

are different varies with products, therefore, please call our Sales staffs for inquiries.

3. Electromagnetic Wave

Applications with strong electromagnetic wave such as, IH cooker, will influence the reliability of LED,

therefore please evaluate before using it.

________________________________________________________

www.rohm.com

10/10

©2022 ROHM Co., Ltd. All rights reserved

2022.2 - Rev.007

�Notice

Notes

1) The information contained herein is subject to change without notice.

2) Before you use our Products, please contact our sales representative and verify the latest specifications.

3) Although ROHM is continuously working to improve product reliability and quality, semiconductors can break down and malfunction due to various factors.

Therefore, in order to prevent personal injury or fire arising from failure, please take safety

measures such as complying with the derating characteristics, implementing redundant and

fire prevention designs, and utilizing backups and fail-safe procedures. ROHM shall have no

responsibility for any damages arising out of the use of our Poducts beyond the rating specified by

ROHM.

4) Examples of application circuits, circuit constants and any other information contained herein are

provided only to illustrate the standard usage and operations of the Products. The peripheral

conditions must be taken into account when designing circuits for mass production.

5) The technical information specified herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or implicitly,

any license to use or exercise intellectual property or other rights held by ROHM or any other

parties. ROHM shall have no responsibility whatsoever for any dispute arising out of the use of

such technical information.

6) The Products are intended for use in general electronic equipment (i.e. AV/OA devices, communication, consumer systems, gaming/entertainment sets) as well as the applications indicated in

this document.

7) The Products specified in this document are not designed to be radiation tolerant.

8) For use of our Products in applications requiring a high degree of reliability (as exemplified

below), please contact and consult with a ROHM representative : transportation equipment (i.e.

cars, ships, trains), primary communication equipment, traffic lights, fire/crime prevention, safety

equipment, medical systems, servers, solar cells, and power transmission systems.

9) Do not use our Products in applications requiring extremely high reliability, such as aerospace

equipment, nuclear power control systems, and submarine repeaters.

10) ROHM shall have no responsibility for any damages or injury arising from non-compliance with

the recommended usage conditions and specifications contained herein.

11) ROHM has used reasonable care to ensure the accuracy of the information contained in this

document. However, ROHM does not warrants that such information is error-free, and ROHM

shall have no responsibility for any damages arising from any inaccuracy or misprint of such

information.

12) Please use the Products in accordance with any applicable environmental laws and regulations,

such as the RoHS Directive. For more details, including RoHS compatibility, please contact a

ROHM sales office. ROHM shall have no responsibility for any damages or losses resulting

non-compliance with any applicable laws or regulations.

13) When providing our Products and technologies contained in this document to other countries,

you must abide by the procedures and provisions stipulated in all applicable export laws and

regulations, including without limitation the US Export Administration Regulations and the Foreign

Exchange and Foreign Trade Act.

14) This document, in part or in whole, may not be reprinted or reproduced without prior consent of

ROHM.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

www.rohm.com

© 2015 ROHM Co., Ltd. All rights reserved.

R1107 A

�Datasheet

General Precaution

1. Before you use our Pro ducts, you are requested to care fully read this document and fully understand its contents.

ROHM shall n ot be in an y way responsible or liabl e for fa ilure, malfunction or acci dent arising from the use of a ny

ROHM’s Products against warning, caution or note contained in this document.

2. All information contained in this docume nt is current as of the issuing date and subj ect to change without any prior

notice. Before purchasing or using ROHM’s Products, please confirm the la test information with a ROHM sale s

representative.

3.

The information contained in this doc ument is provi ded on an “as is” basis and ROHM does not warrant that all

information contained in this document is accurate an d/or error-free. ROHM shall not be in an y way responsible or

liable for an y damages, expenses or losses incurred b y you or third parties resulting from inaccur acy or errors of or

concerning such information.

Notice – WE

© 2015 ROHM Co., Ltd. All rights reserved.

Rev.001

�