POWER DRIVER FOR STEPPER MOTORS

INTEGRATED CIRCUITS

TMC2130-LA DATASHEET

Universal high voltage driver for two-phase bipolar stepper motor. stealthChop™ for quiet

movement. Integrated MOSFETs for up to 2.0A motor current per coil. With Step/Dir Interface and SPI.

APPLICATIONS

Textile, Sewing Machines

Factory & Lab Automation

3D printers

Liquid Handling

Medical

Office Automation

CCTV, Security

ATM, Cash recycler

POS

Pumps and Valves

FEATURES

AND

DESCRIPTION

BENEFITS

The TMC2130 is a high performance driver

IC for two phase stepper motors. Standard

SPI and STEP/DIR simplify communication.

TRINAMICs

sophisticated

stealthChop

chopper ensures noiseless operation

combined with maximum efficiency and

best motor torque. coolStep allows

reducing energy consumption by up to

75%. dcStep drives high loads as fast as

possible without step loss. Integrated

power MOSFETs handle motor currents up

to 1.2A RMS (QFN package) / 1.4A RMS

(TQFP) or 2.5A short time peak current per

coil. Protection and diagnostic features

support robust and reliable operation.

Industries’ most advanced stepper motor

driver enables miniaturized designs with

low external component count for costeffective and highly competitive solutions.

2-phase stepper motors up to 2.0A coil current (2.5A peak)

Step/Dir Interface with microstep interpolation microPlyer™

SPI Interface

Voltage Range 4.75… 46V DC

Highest Resolution 256 microsteps per full step

stealthChop™ for extremely quiet operation and smooth

motion

spreadCycle™ highly dynamic motor control chopper

dcStep™ load dependent speed control

stallGuard2™ high precision sensorless motor load detection

coolStep™ current control for energy savings up to 75%

Integrated Current Sense Option

Passive Braking and freewheeling mode

Full Protection & Diagnostics

Small Size 5x6mm2 QFN36 package or TQFP48 package

BLOCK DIAGRAM

Step/Dir

Power

Supply

+5V Regulator

INT

Interrupt

IREF optional current scaling

Charge

Pump

TMC2130

Step Multiplyer

Standstill Current

Reduction

DAC Reference

Motor

SPI

CLK

SPI Control,

Config & Diags

Control

Register

Set

CLK Oscillator /

Selector

spreadCycle

Programmable

256 µStep

Sequencer

DRIVER

stealthChop

Protection

& Diagnostics

stallGuard2

TRINAMIC Motion Control GmbH & Co. KG

Hamburg, Germany

coolStep

dcStep

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

2

APPLICATION EXAMPLES: HIGH VOLTAGE – MULTIPURPOSE USE

The TMC2130 scores with power density, integrated power MOSFETs, and a versatility that covers a

wide spectrum of applications from battery systems up to embedded applications with 2.0A motor

current per coil. Based on stallGuard2, coolStep, dcStep, spreadCycle, and stealthChop, the TMC2130

optimizes drive performance and keeps costs down. It considers velocity vs. motor load, realizes

energy savings, smoothness of the drive and noiselessness. Extensive support at the chip, board, and

software levels enables rapid design cycles and fast time-to-market with competitive products.

MINIATURIZED DESIGN

FOR ONE

STEPPER MOTOR

In this application, the CPU initializes the

TMC2130 motor driver via SPI interface and

controls motor movement by sending step

and direction signals. A real time software

realizes motion control.

0A+

High-Level

Interface

CPU

S/D

TMC2130

FOR

N

0B+

0B-

SPI

DESIGN

S

0A-

DEMANDING APPLICATIONS

WITH

S-SHAPED RAMP PROFILES

0A+

High-Level

Interface

CPU

SPI

TMC4361

SPI

Motion

Controller

S/D

TMC2130

0A-

S

N

0B+

0B-

SPI

COMPACT DESIGN

FOR UP TO

THREE STEPPER MOTORS

0A+

High-Level

Interface

CPU

SPI

TMC429

Motion

Controller

STEP/

DIR

TMC2130

0A-

S

N

0B+

0B-

SPI

STEP/

DIR

0A+

TMC2130

0A-

S

The CPU initializes the TMC4361 motion

controller and the TMC2130. Thereafter, it

sends target positions to the TMC4361. Now,

the TMC4361 takes control over the TMC2130.

Combining the TMC4361 and the TMC2130

offers diverse possibilities for demanding

applications including servo drive features.

Here, an application with up to three stepper

motors is shown. A single CPU combined

with a TMC429 motion controller manages

the whole stepper motor driver system. This

design is highly economical and space

saving if more than one stepper motor is

needed.

N

0B+

0BSPI

STEP/

DIR

0A+

TMC2130

0A-

S

N

0B+

0BSPI

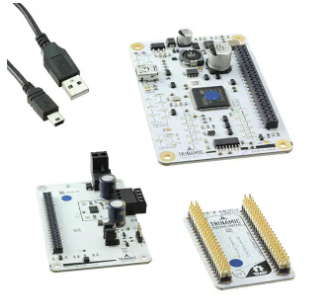

ORDER CODES

Order code

TMC2130-LA

TMC2130-TA

TMC2130-EVAL

TMC4361-EVAL

STARTRAMPE

ESELSBRÜCKE

www.trinamic.com

Description

1-axis dcStep, coolStep, and stealthChop driver; QFN36

1-axis dcStep, coolStep, and stealthChop driver; TQFP48

Evaluation board for TMC2130 two phase stepper motor

controller/driver

Motion controller board (part of evaluation board system)

Baseboard for TMC2130-EVAL and further evaluation boards

Connector board for plug-in evaluation board system

Size [mm2]

5x6

9x9

85 x 55

85 x 55

85 x 55

61 x 38

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

3

Table of Contents

1

2

PRINCIPLES OF OPERATION ......................... 5

8

ANALOG CURRENT CONTROL AIN ............. 54

1.1

KEY CONCEPTS ................................................ 7

1.2

SPI CONTROL INTERFACE ............................... 7

1.3

SOFTWARE ...................................................... 7

1.4

MOVING THE MOTOR ...................................... 7

1.5

STEALTHCHOP DRIVER ..................................... 8

1.6

STALLGUARD2 – MECHANICAL LOAD SENSING8

1.7

COOLSTEP – LOAD ADAPTIVE CURRENT

CONTROL ...................................................................... 8

1.8

DCSTEP – LOAD DEPENDENT SPEED CONTROL 9

9

SELECTING SENSE RESISTORS.................... 55

PIN ASSIGNMENTS .........................................10

2.1

2.2

3

PACKAGE OUTLINE ........................................10

SIGNAL DESCRIPTIONS .................................11

SAMPLE CIRCUITS ..........................................13

3.1

STANDARD APPLICATION CIRCUIT ................13

3.2

REDUCED NUMBER OF COMPONENTS .............14

3.3

INTERNAL RDSON SENSING..........................14

3.4

EXTERNAL 5V POWER SUPPLY ......................15

3.5

PRE-REGULATOR FOR REDUCED POWER

DISSIPATION..............................................................16

3.6

5V ONLY SUPPLY..........................................17

3.7

HIGH MOTOR CURRENT .................................18

3.8

DRIVER PROTECTION AND EME CIRCUITRY ...20

4

SPI INTERFACE ................................................21

4.1

4.2

4.3

5

SPI DATAGRAM STRUCTURE .........................21

SPI SIGNALS ................................................22

TIMING .........................................................23

REGISTER MAPPING .......................................24

5.1

GENERAL CONFIGURATION REGISTERS ..........25

5.2

VELOCITY DEPENDENT DRIVER FEATURE

CONTROL REGISTER SET .............................................27

5.3

SPI MODE REGISTER ....................................29

5.4

DCSTEP MINIMUM VELOCITY REGISTER .........29

5.5

MOTOR DRIVER REGISTERS ...........................30

6

STEALTHCHOP™ ..............................................39

6.1

6.2

6.3

6.4

6.5

6.6

7

TWO MODES FOR CURRENT REGULATION ......39

AUTOMATIC SCALING ....................................40

VELOCITY BASED SCALING ............................42

COMBINING STEALTHCHOP AND SPREADCYCLE

44

FLAGS IN STEALTHCHOP................................45

FREEWHEELING AND PASSIVE MOTOR BRAKING

46

SPREADCYCLE AND CLASSIC CHOPPER ...47

7.1

7.2

7.3

7.4

SPREADCYCLE

CHOPPER ................................48

CLASSIC CONSTANT OFF TIME CHOPPER.......51

RANDOM OFF TIME .......................................52

CHOPSYNC2 FOR QUIET 2-PHASE MOTOR .....53

www.trinamic.com

10

INTERNAL SENSE RESISTORS ................. 57

11

VELOCITY BASED MODE CONTROL ....... 59

12

DRIVER DIAGNOSTIC FLAGS .................. 61

12.1

12.2

12.3

14

14.1

14.2

14.3

14.4

15

15.1

15.2

15.3

16

TEMPERATURE MEASUREMENT ....................... 61

SHORT TO GND PROTECTION ....................... 61

OPEN LOAD DIAGNOSTICS ........................... 61

STALLGUARD2 LOAD MEASUREMENT ... 62

TUNING STALLGUARD2 THRESHOLD SGT ..... 63

STALLGUARD2 UPDATE RATE AND FILTER .... 65

DETECTING A MOTOR STALL ......................... 65

LIMITS OF STALLGUARD2 OPERATION .......... 65

COOLSTEP OPERATION ............................. 66

USER BENEFITS............................................. 66

SETTING UP FOR COOLSTEP .......................... 66

TUNING COOLSTEP........................................ 68

STEP/DIR INTERFACE ................................ 69

16.1 TIMING ......................................................... 69

16.2 CHANGING RESOLUTION ............................... 70

16.3 MICROPLYER STEP INTERPOLATOR AND STAND

STILL DETECTION ....................................................... 71

17

DIAG OUTPUTS ........................................... 72

18

DCSTEP .......................................................... 73

18.1

18.2

18.3

18.4

19

19.1

19.2

USER BENEFITS............................................. 73

DESIGNING-IN DCSTEP ................................. 73

DCSTEP WITH STEP/DIR INTERFACE ........... 74

STALL DETECTION IN DCSTEP MODE ............ 77

SINE-WAVE LOOK-UP TABLE................... 78

USER BENEFITS............................................. 78

MICROSTEP TABLE ........................................ 78

20

EMERGENCY STOP ...................................... 79

21

DC MOTOR OR SOLENOID ....................... 80

21.1

SOLENOID OPERATION.................................. 80

22

QUICK CONFIGURATION GUIDE ............ 81

23

GETTING STARTED ..................................... 84

23.1

INITIALIZATION EXAMPLE ............................. 84

24

STANDALONE OPERATION ...................... 85

25

EXTERNAL RESET ........................................ 88

26

CLOCK OSCILLATOR AND INPUT ........... 88

26.1

27

CONSIDERATIONS ON THE FREQUENCY .......... 88

ABSOLUTE MAXIMUM RATINGS ............ 89

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

28

28.1

28.2

28.3

29

29.1

29.2

29.3

29.4

30

ELECTRICAL CHARACTERISTICS .............89

4

30.1

30.2

30.3

DIMENSIONAL DRAWINGS QFN36 5X6 ....... 97

DIMENSIONAL DRAWINGS TQFP-EP48 ....... 99

PACKAGE CODES ......................................... 100

OPERATIONAL RANGE ...................................89

DC AND TIMING CHARACTERISTICS ..............90

THERMAL CHARACTERISTICS ..........................93

31

DISCLAIMER ............................................... 101

LAYOUT CONSIDERATIONS .....................94

32

ESD SENSITIVE DEVICE.......................... 101

EXPOSED DIE PAD ........................................94

WIRING GND ...............................................94

SUPPLY FILTERING ........................................94

LAYOUT EXAMPLE (QFN36) ..........................95

33

TABLE OF FIGURES .................................. 102

34

REVISION HISTORY ................................. 103

35

REFERENCES ............................................... 103

PACKAGE MECHANICAL DATA ................97

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

1

5

Principles of Operation

THE TMC2130 OFFERS THREE BASIC MODES OF OPERATION:

In Step/Direction Driver Mode, the TMC2130 is the microstep sequencer and power driver between a

motion controller and a two phase stepper motor. Configuration of the TMC2130 is done via SPI. A

dedicated motion controller IC or the CPU sends step and direction signals to the TMC2130. The

TMC2130 provides the related motor coil currents to operate the motor. In Standalone Mode, the

TMC2130 can be configured using pins. In this mode of operation CPU interaction is not necessary.

The third mode of operation is the SPI Driver Mode, which is used in combination with TRINAMICs

TMC4361 motion controller chip. This mode of operation offers several possibilities for sophisticated

applications.

OPERATION MODE 1: Step/Direction Driver Mode

An external motion controller is used or a central CPU generates step and direction signals. The

motion controller (e.g. TMC429) controls the motor position by sending pulses on the STEP signal

while indicating the direction on the DIR signal. The TMC2130 provides a microstep counter and a sine

table to convert these signals into the coil currents which control the position of the motor. The

TMC2130 automatically takes care of intelligent current and mode control and delivers feedback on the

state of the motor. The microPlyer automatically smoothens motion. To optimize power consumption

and heat dissipation, software may also adjust coolStep and stallGuard2 parameters in real-time, for

example to implement different tradeoffs between speed and power consumption.

VCP

100n

CPI

charge pump

CPO

VSA

4.7µ

2R2 and 470n are optional

filtering components for

best chopper precision

AIN_IREF

DIR

F

step multiplier

microPlyer

SPI™

IREF

SCK

PU

SDI

PU

SDO

PU

f ace

Inter

programmable

sine table

4*256 entry

Control register

set

Diganostics

DIAG0

PMD

RS

current

comparator

Stepper driver

Protection

& diagnostics

current

comparator

IREF

DAC

DAC

RS

BRB

DIAG out

stallGuard2™

Half Bridge 2

leave open

PU

DRV_ENN

PU

PU

dcStep control

Tie DCEN to GND if

dcStep is not used

Figure 1.1 TMC2130 STEP/DIR application diagram

www.trinamic.com

DCO

GNDA

DIE PAD

SPI_MODE

TST_MODE

100n

Half Bridge 1

DCIN

PU

VCC_IO

OB2

ISENSE

ISENSE

DCEN

CLK oscillator/

selector

PU=166K pullup to VCC

CLK_IN

phase

stepper

motor

GNDP

coolStep™

dcStep™

opt. ext. clock

10-16MHz

+VIO

3.3V or 5V

I/O voltage

RS=0R15 allows for

maximum coil current.

Use low inductance

SMD resistor type.

Tie BRA and BRB to

GND for internal

2

current sensing

IREF

PDD=100k pulldown

PMD=50k to VCC/2

PDD

BRA

GNDP

spreadCycle &

stealthChop

Chopper

x

OA2

Half Bridge 2

ISENSE

DRV_ENN

SPI interface

B.Dwersteg, ©

TRINAMIC 2014

DIAG1

ISENSE

tep &

coolS Chop

th

steal driver

r

o

t

o

m

PU=166K pullup resistor to VCC

PD=166k pull down resistor to GND

CSN

+VM

OA1

Half Bridge 1

DAC Reference

VCC

PU

5VOUT

100n

2R2

470n

RREF

Optional for internal current

sensing. RREF=9K1 allows for

maximum coil current.

VS

5V Voltage

regulator

5VOUT

optional current scaling

Standstill

current

reduction

22n

100n

STEP

TMC2130

Stepper Motor Driver

+VM

F

F = 60ns spike filter

step & dir input

opt. driver enable

OB1

VS

100n

+VM

S

N

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

6

OPERATION MODE 2: Standalone Mode

The TMC2130 positions the motor based on step and direction signals. The microPlyer automatically

smoothens motion. No CPU interaction is required. Configuration is done by hardware pins. Basic

standby current control can be done by the TMC2130. Optional feedback signals allow error detection

and synchronization.

AIN_IREF

optional current scaling

DIR

STEP

step & dir input

RREF

5VOUT

Optional for internal current

sensing. RREF=9K1 allows for

maximum coil current.

+VM

VCP

100n

charge pump

CPO

CFG1

step multiplier

microPlyer

VSA

4.7µ

2R2

VCC

2R2 and 470n are optional

filtering components for

best chopper precision

470n

TG= toggle with 166K resistor between VCC

and GND to detect open pin

TG

CFG1

TG

CFG2

TG

CFG3

TG

CFG4

TG

CFG5

TG

DRV_ENN_CFG6

TG

TRISTATE configuration

(GND, VCC_IO or open)

Opt. driver

enable input

CFG0

CFG4

Configuration

interface

with TRISTATE

detection

B.Dwersteg, ©

TRINAMIC 2014

PDD=100k pulldown

PMD=50k to VCC/2

Index pulse

Driver error

opt. ext. clock

10-16MHz

+VIO

3.3V or 5V

I/O voltage

DIAG1

PDD

DIAG0

PMD

CLK_IN

IREF

ISENSE

sine table

4*256 entry

CFG2

BRA

ISENSE

RS

GNDP

CFG1

CFG5

spreadCycle &

stealthChop

Chopper

DRV_ENN

Stepper driver

Protection

& diagnostics

x

OA2

Half Bridge 2

CFG0

CFG1

OA1

Half Bridge 1

DAC Reference

le &

dCyc

sprea hChop

t

steal driver

r

o

t

o

m

5V Voltage

regulator

5VOUT

CFG3

Standstill

current

reduction

CFG6

22n

100n

+VM

VS

CFG2

CPI

100n

F

F

F = 60ns spike filter

TMC 2130 Standalone

Stepper Motor Driver

CFG2

current

comparator

current

comparator

IREF

DAC

RS=0R15 allows for

maximum coil

current;

Tie BRA and BRB to

GND for internal

current sensing

DAC

IREF

f ace

Inter

GNDP

S

N

2 phase

stepper

motor

RS

BRB

Half Bridge 2

Status out

(open drain)

OB2

ISENSE

Half Bridge 1

CLK oscillator/

selector

ISENSE

PU

VCC_IO

VS

100n

+VM

GNDA

DIE PAD

TST_MODE

100n

SPI_MODE

OB1

Figure 1.2 TMC2130 standalone driver application diagram

OPERATION MODE 3: SPI Driver Mode

Together with the TMC4361 high-performance S-ramp motion controller the TMC2130 stepper motor

driver offers an SPI control mode, which gives full control over the motor coil currents to the

TMC4361. Combining these two ICs offers several possibilities for demanding applications including

servo features. Please refer to Figure 1.1 for more information about the pinning, which is identical to

step/direction driver mode, except that the STEP & DIR pins are not required for operation.

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

7

1.1 Key Concepts

The TMC2130 implements advanced features which are exclusive to TRINAMIC products. These features

contribute toward greater precision, greater energy efficiency, higher reliability, smoother motion, and

cooler operation in many stepper motor applications.

stealthChop™

No-noise, high-precision chopper algorithm for inaudible motion and inaudible

standstill of the motor.

spreadCycle™

High-precision chopper algorithm for highly dynamic motion and absolutely clean

current wave.

dcStep™

Load dependent speed control. The motor moves as fast as possible and never loses

a step.

stallGuard2™

Sensorless stall detection and mechanical load measurement.

coolStep™

Load-adaptive current control reducing energy consumption by as much as 75%.

microPlyer™

Microstep interpolator for obtaining increased smoothness of microstepping when

using the STEP/DIR interface.

In addition to these performance enhancements, TRINAMIC motor drivers offer safeguards to detect

and protect against shorted outputs, output open-circuit, overtemperature, and undervoltage

conditions for enhancing safety and recovery from equipment malfunctions.

1.2 SPI Control Interface

The SPI interface is a bit-serial interface synchronous to a bus clock. For every bit sent from the bus

master to the bus slave another bit is sent simultaneously from the slave to the master.

Communication between an SPI master and the TMC2130 slave always consists of sending one 40-bit

command word and receiving one 40-bit status word.

The SPI command rate typically is a single initialization after power-on.

1.3 Software

From a software point of view the TMC2130 is a peripheral with a number of control and status

registers. Most of them can either be written only or read only. Some of the registers allow both read

and write access. In case read-modify-write access is desired for a write only register, a shadow

register can be realized in master software.

1.4 Moving the Motor

1.4.1

STEP/DIR Interface

The motor can be controlled by a step and direction input. Active edges on the STEP input can be

rising edges or both rising and falling edges as controlled by a mode bit (dedge). Using both edges

cuts the toggle rate of the STEP signal in half, which is useful for communication over slow interfaces

such as optically isolated interfaces. On each active edge, the state sampled from the DIR input

determines whether to step forward or back. Each step can be a fullstep or a microstep, in which

there are 2, 4, 8, 16, 32, 64, 128, or 256 microsteps per fullstep. A step impulse with a low state on

DIR increases the microstep counter and a high decreases the counter by an amount controlled by the

microstep resolution. An internal table translates the counter value into the sine and cosine values

which control the motor current for microstepping.

1.4.2

SPI Direct Mode

The direct mode allows control of both motor coil currents and polarity via SPI. It mainly is intended

for use with a dedicated external motion controller IC with integrated sequencer. The sequencer

applies sine and cosine waves to the motor coils. This mode also allows control of DC motors, etc.

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

8

1.5 stealthChop Driver

stealthChop is a voltage chopper based principle. It guarantees absolutely quiet motor standstill and

silent slow motion, except for noise generated by ball bearings. stealthChop can be combined with

classic cycle-by-cycle chopper modes for best performance in all velocity ranges. Two additional

chopper modes are available: a traditional constant off-time mode and the spreadCycle mode. The

constant off-time mode provides high torque at highest velocity, while spreadCycle offers smooth

operation and good power efficiency over a wide range of speed and load. spreadCycle automatically

integrates a fast decay cycle and guarantees smooth zero crossing performance. The extremely

smooth motion of stealthChop is beneficial for many applications.

Programmable microstep shapes allow optimizing the motor performance for low cost motors.

Benefits of using stealthChop:

- Significantly improved microstepping with low cost motors

- Motor runs smooth and quiet

- Absolutely no standby noise

- Reduced mechanical resonances yields improved torque

1.6 stallGuard2 – Mechanical Load Sensing

stallGuard2 provides an accurate measurement of the load on the motor. It can be used for stall

detection as well as other uses at loads below those which stall the motor, such as coolStep loadadaptive current reduction. This gives more information on the drive allowing functions like

sensorless homing and diagnostics of the drive mechanics.

1.7 coolStep – Load Adaptive Current Control

coolStep drives the motor at the optimum current. It uses the stallGuard2 load measurement

information to adjust the motor current to the minimum amount required in the actual load situation.

This saves energy and keeps the components cool.

Benefits are:

- Energy efficiency

- Motor generates less heat

- Less or no cooling

- Use of smaller motor

power consumption decreased up to 75%

improved mechanical precision

improved reliability

less torque reserve required → cheaper motor does the job

Figure 1.3 shows the efficiency gain of a 42mm stepper motor when using coolStep compared to

standard operation with 50% of torque reserve. coolStep is enabled above 60RPM in the example.

0,9

Efficiency with coolStep

0,8

Efficiency with 50% torque reserve

0,7

0,6

0,5

Efficiency

0,4

0,3

0,2

0,1

0

0

50

100

150

200

250

300

350

Velocity [RPM]

Figure 1.3 Energy efficiency with coolStep (example)

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

9

1.8 dcStep – Load Dependent Speed Control

dcStep allows the motor to run near its load limit and at its velocity limit without losing a step. If the

mechanical load on the motor increases to the stalling load, the motor automatically decreases

velocity so that it can still drive the load. With this feature, the motor will never stall. In addition to

the increased torque at a lower velocity, dynamic inertia will allow the motor to overcome mechanical

overloads by decelerating. dcStep feeds back status information to the external motion controller or

to the system CPU, so that the target position will be reached, even if the motor velocity needs to be

decreased due to increased mechanical load. A dynamic range of up to factor 10 or more can be

covered by dcStep without any step loss. By optimizing the motion velocity in high load situations,

this feature further enhances overall system efficiency.

Benefits are:

- Motor does not loose steps in overload conditions

- Application works as fast as possible

- Highest possible acceleration automatically

- Highest energy efficiency at speed limit

- Highest possible motor torque using fullstep drive

- Cheaper motor does the job

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

2

10

Pin Assignments

BRA

OA2

VS

VSA

VCP

31

30

29

34

32

OA1

35

33

TST_MODE

GNDP

36

2.1 Package Outline

CLK

1

28

CSN_CFG3

2

27

CPI

CPO

SCK_CFG2

3

26

VCC

25

5VOUT

24

GNDA

23

AIN_IREF

22

DRV_ENN_CFG6

21

DIAG1

20

DIAG0

19

DCIN_CFG5

SDI_CFG1

4

SDO_CFG0

5

STEP

6

TMC2130-LA

QFN-36

DIR

7

5mm x 6mm

VCC_IO

8

-

9

SPI_MODE

10

18

17

16

VS

DCO

DCEN_CFG4

15

OB2

BRB

14

13

OB1

12

-

GNDP

11

PAD = GNDD

OA2

-

VS

VSA

VCP

CPI

41

40

39

38

37

43

42

-

BRA

OA1

46

44

47

45

GNDP

48

Figure 2.1 TMC2130-LA package and pinning QFN36 (5x6mm² body)

TST_MODE

1

36

CLK

2

35

CPO

CSN_CFG3

3

34

VCC

SCK_CFG2

4

33

5VOUT

SDI_CFG1

5

32

GNDA

-

6

31

-

SDO_CFG0

7

30

AIN_IREF

STEP

8

29

DRV_ENN_CFG6

DIR

9

28

-

VCC_IO

10

27

DIAG1

-

11

26

DIAG0

SPI_MODE

12

25

DCIN_CFG5

TMC2130-TA

TQFP-48

9mm x 9mm

17

18

19

20

21

22

-

BRB

-

OB2

-

VS

-

24

16

OB1

23

15

DCO

14

-

DCEN_CFG4

13

GNDP

PAD = GNDD

Figure 2.2 TMC2130-TA package and pinning TQFP-EP 48-EP (7x7mm² body, 9x9mm² with leads)

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

11

2.2 Signal Descriptions

Pin

QFN36

TQFP48

Type

CLK

1

2

DI

CSN_CFG3

2

3

SCK_CFG2

3

4

SDI_CFG1

4

5

SDO_CFG0

5

7

STEP

DIR

VCC_IO

6

7

8

8

9

10

11,

18,

28,

45,

DNC

9

DI

(tpu)

DI

(tpu)

DI

(tpu)

DIO

(tpu)

DI

DI

14, 16,

20, 22,

41, 43,

47

-

DI

(pu)

SPI_MODE

10

12

N.C.

11

6, 31, 36

GNDP

OB1

12, 35

13

13, 48

15

BRB

14

17

OB2

15

19

VS

16, 31

21, 40

DCO

17

23

DIO

DCEN_CFG4

18

24

DI

(tpu)

DCIN_CFG5

19

25

DI

(tpu)

DIAG0

20

26

DIO

DIAG1

21

27

DIO

DRV_ENN_

CFG6

22

29

DI

(tpu)

AIN_IREF

23

30

AI

www.trinamic.com

Function

CLK input. Tie to GND using short wire for internal clock

or supply external clock.

SPI chip select input (negative active) (SPI_MODE=1) or

Configuration input (SPI_MODE=0) (tristate detection).

SPI serial clock input (SPI_MODE=1) or

Configuration input (SPI_MODE=0) (tristate detection).

SPI data input (SPI_MODE=1) or

Configuration input (SPI_MODE=0) (tristate detection).

SPI data output (tristate) (SPI_MODE=1) or

Configuration input (SPI_MODE=0) (tristate detection).

STEP input

DIR input

3.3V to 5V IO supply voltage for all digital pins.

Do not connect. Leave open to ensure highest distance

for high voltage pins in TQFP package!

Mode selection input with pullup resistor. When tied low,

the chip is in standalone mode and pins have their CFG

functions. When tied high, the SPI interface is available

for control. Integrated pull-up resistor.

Unused pin, connect to GND for compatibility to future

versions.

Power GND. Connect to GND plane near pin.

Motor coil B output 1

Sense resistor connection for coil B. Place sense resistor

to GND near pin. An additional 100nF capacitor to GND

(GND plane) is recommended for best performance.

Motor coil B output 2

Motor supply voltage. Provide filtering capacity near pin

with short loop to nearest GNDP pin (respectively via GND

plane).

dcStep ready output

dcStep enable input (SPI_MODE=1) - tie to GND for normal

operation (no dcStep) or

Configuration input (SPI_MODE=0) (tristate detection).

dcStep gating input for axis synchronization (SPI_MODE=1)

or

Configuration input (SPI_MODE=0) (tristate detection).

Diagnostics output DIAG0. Use external pull-up resistor

with 47k or less in open drain mode.

Diagnostics output DIAG1. Use external pull-up resistor

with 47k or less in open drain mode.

Enable input (SPI_MODE=1) or

configuration / Enable input (SPI_MODE=0) (tristate

detection).

The power stage becomes switched off (all motor outputs

floating) when this pin becomes driven to a high level.

Analog reference voltage for current scaling (optional

mode) or reference current for use of internal sense

resistors

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

Pin

GNDA

QFN36

24

TQFP48

32

5VOUT

25

33

VCC

26

34

CPO

27

35

CPI

28

37

VCP

29

38

VSA

30

39

OA2

32

42

BRA

33

44

OA1

TST_MODE

34

36

46

1

Exposed

die pad

-

-

Type

DI

12

Function

Analog GND. Tie to GND plane.

Output of internal 5V regulator. Attach 2.2µF or larger

ceramic capacitor to GNDA near to pin for best

performance. May be used to supply VCC of chip.

5V supply input for digital circuitry within chip and

charge pump. Attach 470nF capacitor to GND (GND plane).

May be supplied by 5VOUT. A 2.2 or 3.3 Ohm resistor is

recommended for decoupling noise from 5VOUT. When

using an external supply, make sure, that VCC comes up

before or in parallel to 5VOUT or VCC_IO, whichever

comes up later!

Charge pump capacitor output.

Charge pump capacitor input. Tie to CPO using 22nF 50V

capacitor.

Charge pump voltage. Tie to VS using 100nF capacitor.

Analog supply voltage for 5V regulator. Normally tied to

VS. Provide a 100nF filtering capacitor.

Motor coil A output 2

Sense resistor connection for coil A. Place sense resistor

to GND near pin. An additional 100nF capacitor to GND

(GND plane) is recommended for best performance.

Motor coil A output 1

Test mode input. Tie to GND using short wire.

Connect the exposed die pad to a GND plane. Provide as

many as possible vias for heat transfer to GND plane.

Serves as GND pin for digital circuitry.

*(pu) denominates a pin with pullup resistor; (tpu) denominates a pin with pullup resistor or toggle

detection. Toggle detection is active in standalone mode, only (SPI_MODE=0)

* Digital Pins: All pins of type DI, DI(pu), DI(tpu), DIO and DIO(tpu) refer to VCC_IO and have intrinsic

protective clamping diodes to GND and VCC_IO and use Schmitt trigger inputs.

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

3

13

Sample Circuits

The sample circuits show the connection of external components in different operation and supply

modes. The connection of the bus interface and further digital signals is left out for clarity.

Optional use lower

voltage down to 6V

VCP

CPI

CPO

AIN_IREF

22n

63V

+VM

100n

16V

+VM

VS

VSA

5VOUT

100n

DIR

STEP

3.1 Standard Application Circuit

4.7µ

5V Voltage

regulator

Step & Dir input

with microPlyer

charge pump

DAC Reference

100n

100n

100µF

IREF

2R2

VCC

OA1

TMC2130

470n

CSN

SCK

SDI

SDO

OA2

S

N

stepper

motor

SPI interface

Use low inductivity SMD

type, e.g. 1206, 0.5W

Sequencer

DIAG1

Full Bridge A

BRA

Driver

RSA

B.Dwersteg, ©

TRINAMIC 2014

DIAG / INT out

DIAG0

OB1

Full Bridge B

opt. ext. clock

12-16MHz

+VIO

3.3V or 5V

I/O voltage

OB2

CLK_IN

dcStep Controller

Interface

Use low inductivity SMD

type, e.g. 1206, 0.5W

VCC_IO

BRB

RSB

leave open

opt. dcStep control

GNDP

GNDA

DIE PAD

TST_MODE

DRV_ENN

DCO

DC_IN

DC_EN

SPI_MODE

100n

opt. driver enable

Figure 3.1 Standard application circuit

The standard application circuit uses a minimum set of additional components. Two sense resistors

set the motor coil current. See chapter 9 to choose the right sense resistors. Use low ESR capacitors

for filtering the power supply. The capacitors need to cope with the current ripple cause by chopper

operation. A minimum capacity of 100µF near the driver is recommended for best performance.

Current ripple in the supply capacitors also depends on the power supply internal resistance and

cable length. VCC_IO can be supplied from 5VOUT, or from an external source, e.g. a low drop 3.3V

regulator. In order to minimize linear voltage regulator power dissipation of the internal 5V voltage

regulator in applications where VM is high, a different (lower) supply voltage can be used for VSA, if

available. For example, many applications provide a 12V supply in addition to a higher driver supply

voltage. Using the 12V supply for VSA rather than 24V will reduce the power dissipation of the

internal 5V regulator to about 37% of the dissipation caused by supply with the full motor voltage.

Basic layout hints

Place sense resistors and all filter capacitors as close as possible to the related IC pins. Use a solid

common GND for all GND connections, also for sense resistor GND. Connect 5VOUT filtering capacitor

directly to 5VOUT and GNDA pin. See layout hints for more details. Low ESR electrolytic capacitors are

recommended for VS filtering.

Attention

In case VSA is supplied by a different voltage source, make sure that VSA does not exceed VS by

more than one diode drop, especially also upon power up or power down.

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

14

3.2 Reduced Number of Components

Optional use lower

voltage down to 6V

+VM

VSA

5VOUT

100n

5V Voltage

regulator

4.7µ

VCC

Figure 3.2 Reduced number of filtering components

The standard application circuit uses RC filtering to de-couple the output of the internal linear

regulator from high frequency ripple caused by digital circuitry supplied by the VCC input. For cost

sensitive applications, the RC-Filtering on VCC can be eliminated. This leads to more noise on 5VOUT

caused by operation of the charge pump and the internal digital circuitry. There is a slight impact on

microstep vibration and chopper noise performance.

3.3 Internal RDSon Sensing

5VOUT

For cost critical or space limited applications, sense resistors can be omitted. For internal current

sensing, a reference current set by a tiny external resistor programs the output current. For calculation

of the reference resistor, refer chapter 10.

AIN_IREF

RREF

DAC Reference

IREF

OA1

Full Bridge A

OA2

S

N

stepper

motor

BRA

Driver

OB1

Full Bridge B

OB2

BRB

Figure 3.3 RDSon based sensing eliminates high current sense resistors

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

15

3.4 External 5V Power Supply

When an external 5V power supply is available, the power dissipation caused by the internal linear

regulator can be eliminated. This especially is beneficial in high voltage applications, and when

thermal conditions are critical. There are two options for using an external 5V source: either the

external 5V source is used to support the digital supply of the driver by supplying the VCC pin, or the

complete internal voltage regulator becomes bridged and is replaced by the external supply voltage.

3.4.1

Support for the VCC Supply

This scheme uses an external supply for all digital circuitry within the driver (Figure 3.4). As the digital

circuitry makes up for most of the power dissipation, this way the internal 5V regulator sees only low

remaining load. The precisely regulated voltage of the internal regulator is still used as the reference

for the motor current regulation as well as for supplying internal analog circuitry.

When cutting VCC from 5VOUT, make sure that the VCC supply comes up before or synchronously

with the 5VOUT supply to ensure a correct power up reset of the internal logic. A simple schematic

uses two diodes forming an OR of the internal and the external power supplies for VCC. In order to

prevent the chip from drawing part of the power from its internal regulator, a low drop 1A Schottky

diode is used for the external 5V supply path, while a silicon diode is used for the 5VOUT path. An

enhanced solution uses a dual PNP transistor as an active switch. It minimizes voltage drop and thus

gives best performance.

In certain setups, switching of VCC voltage can be eliminated. A third variant uses the VCC_IO supply

to ensure power-on reset. This is possible, if VCC_IO comes up synchronously with or delayed to VCC.

Use a linear regulator to generate a 3.3V VCC_IO from the external 5V VCC source. This 3.3V regulator

will cause a certain voltage drop. A voltage drop in the regulator of 0.9V or more (e.g. LD1117-3.3)

ensures that the 5V supply already has exceeded the lower limit of about 3.0V once the reset

conditions ends. The reset condition ends earliest, when VCC_IO exceeds the undervoltage limit of

minimum 2.1V. Make sure that the power-down sequence also is safe. Undefined states can result

when VCC drops well below 4V without safely triggering a reset condition. Triggering a reset upon

power-down can be ensured when VSA goes down synchronously with or before VCC.

+VM

+VM

VSA

5VOUT

+5V

100n

4.7µ

VSA

5V Voltage

regulator

5VOUT

+5V

LL4448

100n

4.7µ

VCC

MSS1P3

5V Voltage

regulator

VCC

VCC_IO

3.3V

regulator

470n

470n

100n

3.3V

VCC supplied from external 5V. 5V or 3.3V IO voltage.

VCC supplied from external 5V. 3.3V IO voltage generated from same source.

+VM

VSA

5VOUT

100n

5V Voltage

regulator

4.7µ

+5V

BAT54

10k

VCC

2x BC857 or

1x BC857BS

470n

4k7

VCC supplied from external 5V using active switch. 5V or 3.3V IO voltage.

Figure 3.4 Using an external 5V supply for digital circuitry of driver (different options)

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

3.4.2

16

Internal Regulator Bridged

In case a clean external 5V supply is available, it can be used for complete supply of analog and

digital part (Figure 3.5). The circuit will benefit from a well-regulated supply, e.g. when using a +/-1%

regulator. A precise supply guarantees increased motor current precision, because the voltage at

5VOUT directly is the reference voltage for all internal units of the driver, especially for motor current

control. For best performance, the power supply should have low ripple to give a precise and stable

supply at 5VOUT pin with remaining ripple well below 5mV. Some switching regulators have a higher

remaining ripple, or different loads on the supply may cause lower frequency ripple. In this case,

increase capacity attached to 5VOUT. In case the external supply voltage has poor stability or low

frequency ripple, this would affect the precision of the motor current regulation as well as add

chopper noise.

Well-regulated, stable

supply, better than +-5%

+5V

VSA

5VOUT

4.7µ

5V Voltage

regulator

10R

VCC

470n

Figure 3.5 Using an external 5V supply to bypass internal regulator

3.5 Pre-Regulator for Reduced Power Dissipation

When operating at supply voltages up to 46V for VS and VSA, the internal linear regulator will

contribute with up to 1W to the power dissipation of the driver. This will reduce the capability of the

chip to continuously drive high motor current, especially at high environment temperatures. When no

external power supply in the range 5V to 24V is available, an external pre-regulator can be built with

a few inexpensive components in order to dissipate most of the voltage drop in external components.

Figure 3.6 shows different examples. In case a well-defined supply voltage is available, a single 1W or

higher power Zener diode also does the job.

+VM

+VM

22k

BCX56 or

similar

22k

BCX56 or

similar

4k7

Z5.6V e.g.

MM5Z5V6

VSA

5VOUT

470n

16V

4.7µ

5V Voltage

regulator

2R2

100R

VSA

5VOUT

470n

16V

4.7µ

VCC

470n

Simple pre-regulator for 24V up to 46V

Figure 3.6 Examples for simple pre-regulators

www.trinamic.com

5V Voltage

regulator

2R2

VCC

470n

Simple short circuit protected pre-regulator for 24V up to 46V

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

17

VCP

22n

63V

CPI

CPO

AIN_IREF

DIR

STEP

3.6 5V Only Supply

+5V

100n

16V

+5V

VS

VSA

5VOUT

5V Voltage

regulator

Step & Dir input

with microPlyer

charge pump

DAC Reference

4.7µ

100n

100n

100µF

IREF

VCC

OA1

TMC2130

470n

CSN

SCK

SDI

SDO

SPI interface

OA2

S

N

stepper

motor

Use low inductivity SMD

type, e.g. 1206, 0.5W

Sequencer

DIAG1

Full Bridge A

BRA

Driver

RSA

DIAG / INT out

DIAG0

OB1

Full Bridge B

opt. ext. clock

12-16MHz

+VIO

3.3V or 5V

I/O voltage

OB2

CLK_IN

dcStep Controller

Interface

VCC_IO

A

B

Use low inductivity SMD

type, e.g. 1206, 0.5W

BRB

N

RSB

leave open

opt. dcStep control

GNDP

GNDA

DIE PAD

TST_MODE

DRV_ENN

DCO

DC_IN

DC_EN

SPI_MODE

100n

opt. driver enable

Figure 3.7 5V only operation

While the standard application circuit is limited to roughly 5.5 V lower supply voltage, a 5 V only

application lets the IC run from a normal 5 V +/-5% supply. In this application, linear regulator drop

must be minimized. Therefore, the major 5 V load is removed by supplying VCC directly from the

external supply. In order to keep supply ripple away from the analog voltage reference, 5VOUT should

have an own filtering capacity and the 5VOUT pin does not become bridged to the 5V supply.

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

18

3.7 High Motor Current

When operating at a high motor current, the driver power dissipation due to MOSFET switch onresistance significantly heats up the driver. This power dissipation will heat up the PCB cooling

infrastructure also, if operated at an increased duty cycle. This in turn leads to a further increase of

driver temperature. An increase of temperature by about 100°C increases MOSFET resistance by

roughly 50%. This is a typical behavior of MOSFET switches. Therefore, under high duty cycle, high

load conditions, thermal characteristics have to be carefully taken into account, especially when

increased environment temperatures are to be supported. Refer the thermal characteristics and the

layout hints for more information. As a thumb rule, thermal properties of the PCB design become

critical for the QFN-36 at or above about 1000mA RMS motor current for increased periods of time.

Keep in mind that resistive power dissipation raises with the square of the motor current. On the

other hand, this means that a small reduction of motor current significantly saves heat dissipation

and energy.

An effect which might be perceived at medium motor velocities and motor sine wave peak currents

above roughly 1.2A peak is a slight sine distortion of the current wave when using spreadCycle. It

results from an increasing negative impact of parasitic internal diode conduction, which in turn

negatively influences the duration of the fast decay cycle of the spreadCycle chopper. This is, because

the current measurement does not see the full coil current during this phase of the sine wave,

because an increasing part of the current flows directly from the power MOSFETs’ drain to GND and

does not flow through the sense resistor. This effect with most motors does not negatively influence

the smoothness of operation, as it does not impact the critical current zero transition. The effect does

not occur with stealthChop.

3.7.1

Reduce Linear Regulator Power Dissipation

When operating at high supply voltages, as a first step the power dissipation of the integrated 5V

linear regulator can be reduced, e.g. by using an external 5V source for supply. This will reduce overall

heating. It is advised to reduce motor stand still current in order to decrease overall power

dissipation. If applicable, also use coolStep. A decreased clock frequency will reduce power dissipation

of the internal logic. Further a decreased chopper frequency also can reduce power dissipation.

3.7.2

Operation near to / above 2A Peak Current

The driver can deliver up to 2.5A motor peak current. Considering thermal characteristics, this only is

possible in duty cycle limited operation. When a peak current up to 2.5A is to be driven, the driver

chip temperature is to be kept at a maximum of 105°C. Linearly derate the design peak temperature

from 125°C to 105°C in the range 2A to 2.5A output current (see Figure 3.8). Exceeding this may lead

to triggering the short circuit detection.

Limit by lower limit of

overtemperature threshold

High temperature

range

125°C

115°C

d

de

en e

m tim

om of

ec s

t r i od

no er

n dp

tio e

ra as

ea cre

Op r in

fo

Die

Temperature

135°C

Specified operational

range for max. 125°C

105°C

1.5A 1.75A

2A

Current

limitation

Derating

for >2A

2.25A 2.5A Peak coil

current

Figure 3.8 Derating of maximum sine wave peak current at increased die temperature

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

3.7.3

19

Reduction of Resistive Losses by Adding Schottky Diodes

Schottky Diodes can be added to the circuit to reduce driver power dissipation when driving high

motor currents (see Figure 3.9). The Schottky diodes have a conduction voltage of about 0.5V and will

take over more than half of the motor current during the negative half wave of each output in slow

decay and fast decay phases, thus leading to a cooler motor driver. This effect starts from a few

percent at 1.2A and increases with higher motor current rating up to roughly 20%. As a 30V Schottky

diode has a lower forward voltage than a 50V or 60V diode, it makes sense to use a 30V diode when

the supply voltage is below 30V. The diodes will have less effect when working with stealthChop due

to lower times of diode conduction in the chopper cycle. At current levels below 1.2A coil current, the

effect of the diodes is negligible.

OA1

Full Bridge A

OA2

BRA

Driver

S

N

stepper

motor

RSA

OB1

Full Bridge B

OB2

1A Schottky Diodes like MSS1P6

or MSS1P3 (VM limited to 30V)

BRB

RSB

Figure 3.9 Schottky diodes reduce power dissipation at high peak currents up to 2A (2.5A)

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

20

3.8 Driver Protection and EME Circuitry

Some applications have to cope with ESD events caused by motor operation or external influence.

Despite ESD circuitry within the driver chips, ESD events occurring during operation can cause a reset

or even a destruction of the motor driver, depending on their energy. Especially plastic housings and

belt drive systems tend to cause ESD events of several kV. It is best practice to avoid ESD events by

attaching all conductive parts, especially the motors themselves to PCB ground, or to apply electrically

conductive plastic parts. In addition, the driver can be protected up to a certain degree against ESD

events or live plugging / pulling the motor, which also causes high voltages and high currents into

the motor connector terminals. A simple scheme uses capacitors at the driver outputs to reduce the

dV/dt caused by ESD events. Larger capacitors will bring more benefit concerning ESD suppression,

but cause additional current flow in each chopper cycle, and thus increase driver power dissipation,

especially at high supply voltages. The values shown are example values – they might be varied

between 100pF and 1nF. The capacitors also dampen high frequency noise injected from digital parts

of the application PCB circuitry and thus reduce electromagnetic emission. A more elaborate scheme

uses LC filters to de-couple the driver outputs from the motor connector. Varistors in between of the

coil terminals eliminate coil overvoltage caused by live plugging. Optionally protect all outputs by a

varistor against ESD voltage.

470pF

100V

OA1

Full Bridge A

OA1

OA2

S

N

stepper

motor

Full Bridge A

50Ohm @

100MHz

V1A

V1

OA2

50Ohm @

100MHz

470pF

100V

BRA

Driver

RSA

470pF

100V

S

N

stepper

motor

V1B

470pF

100V

Driver

100nF

16V

470pF

100V

OB1

Full Bridge B

OB1

Full Bridge B

OB2

50Ohm @

100MHz

V2A

V2

OB2

50Ohm @

100MHz

470pF

100V

BRB

RSB

100nF

16V

470pF

100V

V2B

470pF

100V

Fit varistors to supply voltage

rating. SMD inductivities

conduct full motor coil

current.

Figure 3.10 Simple ESD enhancement and more elaborate motor output protection

www.trinamic.com

Varistors V1 and V2 protect

against inductive motor coil

overvoltage.

V1A, V1B, V2A, V2B:

Optional position for varistors

in case of heavy ESD events.

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

4

21

SPI Interface

4.1 SPI Datagram Structure

The TMC2130 uses 40 bit SPI™ (Serial Peripheral Interface, SPI is Trademark of Motorola) datagrams

for communication with a microcontroller. Microcontrollers which are equipped with hardware SPI are

typically able to communicate using integer multiples of 8 bit. The NCS line of the device must be

handled in a way, that it stays active (low) for the complete duration of the datagram transmission.

Each datagram sent to the device is composed of an address byte followed by four data bytes. This

allows direct 32 bit data word communication with the register set. Each register is accessed via 32

data bits even if it uses less than 32 data bits.

For simplification, each register is specified by a one byte address:

- For a read access the most significant bit of the address byte is 0.

- For a write access the most significant bit of the address byte is 1.

Most registers are write only registers, some can be read additionally, and there are also some read

only registers.

SPI DATAGRAM STRUCTURE

MSB (transmitted first)

40 bit

39 ...

→ 8 bit address

8 bit SPI status

... 0

→ 32 bit data

39 ... 32

→ to TMC2130

RW + 7 bit address

from TMC2130

8 bit SPI status

W

39 / 38 ... 32

38...32

LSB (transmitted last)

31 ... 0

8 bit data

8 bit data

31 ... 24

31...28

27...24

23 ... 16

23...20

19...16

8 bit data

8 bit data

15 ... 8

15...12

7 ... 0

11...8

7...4

3...0

3 3 3 3 3 3 3 3 3 3 2 2 2 2 2 2 2 2 2 2 1 1 1 1 1 1 1 1 1 1

9 8 7 6 5 4 3 2 1 0

9 8 7 6 5 4 3 2 1 0 9 8 7 6 5 4 3 2 1 0 9 8 7 6 5 4 3 2 1 0

4.1.1

Selection of Write / Read (WRITE_notREAD)

The read and write selection is controlled by the MSB of the address byte (bit 39 of the SPI

datagram). This bit is 0 for read access and 1 for write access. So, the bit named W is a

WRITE_notREAD control bit. The active high write bit is the MSB of the address byte. So, 0x80 has to

be added to the address for a write access. The SPI interface always delivers data back to the master,

independent of the W bit. The data transferred back is the data read from the address which was

transmitted with the previous datagram, if the previous access was a read access. If the previous

access was a write access, then the data read back mirrors the previously received write data. So, the

difference between a read and a write access is that the read access does not transfer data to the

addressed register but it transfers the address only and its 32 data bits are dummies, and, further the

following read or write access delivers back the data read from the address transmitted in the

preceding read cycle.

A read access request datagram uses dummy write data. Read data is transferred back to the master

with the subsequent read or write access. Hence, reading multiple registers can be done in a

pipelined fashion.

Whenever data is read from or written to the TMC2130, the MSBs delivered back contain the SPI

status, SPI_STATUS, a number of eight selected status bits.

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

22

Example:

For a read access to the register (DRV_STATUS) with the address 0x6F, the address byte has

to be set to 0x6F in the access preceding the read access. For a write access to the register

(CHOPCONF), the address byte has to be set to 0x80 + 0x6C = 0xEC. For read access, the data

bit might have any value (-). So, one can set them to 0.

action

read DRV_STATUS

read DRV_STATUS

write CHOPCONF:= 0x00ABCDEF

write CHOPCONF:= 0x00123456

data sent to TMC2130

→ 0x6F00000000

→ 0x6F00000000

→ 0xEC00ABCDEF

→ 0xEC00123456

data received from TMC2130

0xSS & unused data

0xSS & DRV_STATUS

0xSS & DRV_STATUS

0xSS00ABCDEF

*)S: is a placeholder for the status bits SPI_STATUS

4.1.2

SPI Status Bits Transferred with Each Datagram Read Back

New status information becomes latched at the end of each access and is available with the next SPI

transfer.

SPI_STATUS – status flags transmitted with each SPI access in bits 39 to 32

Bit

7

6

5

4

3

2

1

0

Name

Comment

standstill

sg2

driver_error

reset_flag

unused

unused

unused

unused

DRV_STATUS[31] – 1: Signals motor stand still

DRV_STATUS[24] – 1: Signals stallguard flag active

GSTAT[1] – 1: Signals driver 1 driver error (clear by reading GSTAT)

GSTAT[0] – 1: Signals, that a reset has occurred (clear by reading GSTAT)

4.1.3

Data Alignment

All data are right aligned. Some registers represent unsigned (positive) values, some represent integer

values (signed) as two’s complement numbers, single bits or groups of bits are represented as single

bits respectively as integer groups.

4.2 SPI Signals

The SPI bus on the TMC2130 has four signals:

- SCK – bus clock input

- SDI – serial data input

- SDO – serial data output

- CSN – chip select input (active low)

The slave is enabled for an SPI transaction by a low on the chip select input CSN. Bit transfer is

synchronous to the bus clock SCK, with the slave latching the data from SDI on the rising edge of SCK

and driving data to SDO following the falling edge. The most significant bit is sent first. A minimum

of 40 SCK clock cycles is required for a bus transaction with the TMC2130.

If more than 40 clocks are driven, the additional bits shifted into SDI are shifted out on SDO after a

40-clock delay through an internal shift register. This can be used for daisy chaining multiple chips.

CSN must be low during the whole bus transaction. When CSN goes high, the contents of the internal

shift register are latched into the internal control register and recognized as a command from the

master to the slave. If more than 40 bits are sent, only the last 40 bits received before the rising edge

of CSN are recognized as the command.

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

23

4.3 Timing

The SPI interface is synchronized to the internal system clock, which limits the SPI bus clock SCK to

half of the system clock frequency. If the system clock is based on the on-chip oscillator, an additional

10% safety margin must be used to ensure reliable data transmission. All SPI inputs as well as the

ENN input are internally filtered to avoid triggering on pulses shorter than 20ns. Figure 4.1 shows the

timing parameters of an SPI bus transaction, and the table below specifies their values.

CSN

tCC

tCL

tCH

tCH

tCC

SCK

tDU

SDI

bit39

tDH

bit38

bit0

tDO

SDO

tZC

bit39

bit38

bit0

Figure 4.1 SPI timing

Hint

Usually this SPI timing is referred to as SPI MODE 3

SPI interface timing

Parameter

SCK valid before or after change

of CSN

AC-Characteristics

clock period: tCLK

Symbol

tCC

fSCK

fSCK

assumes

synchronous CLK

tCSH

SCK low time

tCL

SCK high time

tCH

www.trinamic.com

Min

Typ

Max

10

*) Min time is for

synchronous CLK

with SCK high one

tCH before CSN high

only

*) Min time is for

synchronous CLK

only

*) Min time is for

synchronous CLK

only

assumes minimum

OSC frequency

CSN high time

SCK frequency using internal

clock

SCK frequency using external

16MHz clock

SDI setup time before rising

edge of SCK

SDI hold time after rising edge

of SCK

Data out valid time after falling

SCK clock edge

SDI, SCK and CSN filter delay

time

Conditions

Unit

ns

tCLK*)

>2tCLK+10

ns

tCLK*)

>tCLK+10

ns

tCLK*)

>tCLK+10

ns

4

MHz

8

MHz

tDU

10

ns

tDH

10

ns

tDO

no capacitive load

on SDO

tFILT

rising and falling

edge

12

20

tFILT+5

ns

30

ns

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

5

24

Register Mapping

This chapter gives an overview of the complete register set. Some of the registers bundling a number

of single bits are detailed in extra tables. The functional practical application of the settings is detailed

in dedicated chapters.

Note

- All registers become reset to 0 upon power up, unless otherwise noted.

- Add 0x80 to the address Addr for write accesses!

NOTATION OF HEXADECIMAL AND BINARY NUMBERS

0x

%

precedes a hexadecimal number, e.g. 0x04

precedes a multi-bit binary number, e.g. %100

NOTATION OF R/W FIELD

R

W

R/W

R+C

Read only

Write only

Read- and writable register

Clear upon read

OVERVIEW REGISTER MAPPING

REGISTER

DESCRIPTION

General Configuration Registers

These registers contain

global configuration

global status flags

interface configuration

and I/O signal configuration

This register set offers registers for

driver current control

setting thresholds for coolStep operation

setting thresholds for different chopper modes

setting thresholds for dcStep operation

This register set offers registers for

setting / reading out microstep table and

counter

chopper and driver configuration

coolStep and stallGuard2 configuration

dcStep configuration

reading out stallGuard2 values and driver error

flags

Setting for minimum dcStep velocity

Velocity Dependent Driver Feature Control Register

Set

Motor Driver Register Set

dcStep Minimum Velocity

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

25

5.1 General Configuration Registers

GENERAL CONFIGURATION REGISTERS (0X00…0X0F)

R/W

Addr

n

RW

0x00

17

Register

GCONF

Description / bit names

Bit

GCONF – Global configuration flags

0 I_scale_analog

0:

Normal operation, use internal reference voltage

1:

Use voltage supplied to AIN as current reference

1 internal_Rsense

0:

Normal operation

1:

Internal sense resistors. Use current supplied into

AIN as reference for internal sense resistor

2 en_pwm_mode

1:

stealthChop voltage PWM mode enabled

(depending on velocity thresholds). Switch from

off to on state while in stand still, only.

3 enc_commutation (Special mode - do not use, leave 0)

1:

Enable commutation by full step encoder

(DCIN_CFG5 = ENC_A, DCEN_CFG4 = ENC_B)

4 shaft

1:

Inverse motor direction

5 diag0_error

1:

Enable DIAG0 active on driver errors:

Over temperature (ot), short to GND (s2g),

undervoltage chargepump (uv_cp)

DIAG0 always shows the reset-status, i.e. is active low

during reset condition.

6 diag0_otpw

1:

Enable DIAG0 active on driver over temperature

prewarning (otpw)

7 diag0_stall

1:

Enable DIAG0 active on motor stall (set

TCOOLTHRS before using this feature)

8 diag1_stall

1:

Enable DIAG1 active on motor stall (set

TCOOLTHRS before using this feature)

9 diag1_index

1:

Enable DIAG1 active on index position (microstep

look up table position 0)

10 diag1_onstate

1:

Enable DIAG1 active when chopper is on (for the

coil which is in the second half of the fullstep)

11

12

13

14

www.trinamic.com

diag1_steps_skipped

1:

Enable output toggle when steps are skipped in

dcStep mode (increment of LOST_STEPS). Do not

enable in conjunction with other DIAG1 options.

diag0_int_pushpull

0:

DIAG0 is open collector output (active low)

1:

Enable DIAG0 push pull output (active high)

diag1_pushpull

0:

DIAG1 is open collector output (active low)

1:

Enable DIAG1 push pull output (active high)

small_hysteresis

0:

Hysteresis for step frequency comparison is 1/16

1:

Hysteresis for step frequency comparison is 1/32

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

26

GENERAL CONFIGURATION REGISTERS (0X00…0X0F)

R/W

Addr

n

Register

R+C

0x01

3

GSTAT

R

0x04

8

+

8

IOIN

www.trinamic.com

Description / bit names

15 stop_enable

0:

Normal operation

1:

Emergency stop: DCIN stops the sequencer when

tied high (no steps become executed by the

sequencer, motor goes to standstill state).

16 direct_mode

0:

Normal operation

1:

Motor coil currents and polarity directly

programmed via serial interface: Register XDIRECT

(0x2D) specifies signed coil A current (bits 8..0)

and coil B current (bits 24..16). In this mode, the

current is scaled by IHOLD setting. Velocity based

current regulation of stealthChop is not available

in this mode. The automatic stealthChop current

regulation will work only for low stepper motor

velocities.

17 test_mode

0:

Normal operation

1:

Enable analog test output on pin DCO. IHOLD[1..0]

selects the function of DCO:

0…2: T120, DAC, VDDH

Attention: Not for user, set to 0 for normal operation!

Bit

GSTAT – Global status flags

0 reset

1:

Indicates that the IC has been reset since the last

read access to GSTAT. All registers have been

cleared to reset values.

1 drv_err

1:

Indicates, that the driver has been shut down

due to overtemperature or short circuit detection

since the last read access. Read DRV_STATUS for

details. The flag can only be reset when all error

conditions are cleared.

2 uv_cp

1:

Indicates an undervoltage on the charge pump.

The driver is disabled in this case.

Bit

INPUT

Reads the state of all input pins available

0 STEP

1 DIR

2 DCEN_CFG4

3 DCIN_CFG5

4 DRV_ENN_CFG6

5 DCO

6 This bit always shows 1.

7 Don’t care.

31.. VERSION: 0x11=first version of the IC

24 Identical numbers mean full digital compatibility.

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

27

5.2 Velocity Dependent Driver Feature Control Register Set

VELOCITY DEPENDENT DRIVER FEATURE CONTROL REGISTER SET (0X10…0X1F)

R/W

W

Addr

n

0x10

5

+

5

+

4

Register

Description / bit names

Bit

IHOLD_IRUN – Driver current control

4..0 IHOLD

Standstill current (0=1/32…31=32/32)

In combination with stealthChop mode, setting

IHOLD=0 allows to choose freewheeling or coil

short circuit for motor stand still.

12..8 IRUN

Motor run current (0=1/32…31=32/32)

IHOLD_IRUN

19..16

Hint: Choose sense resistors in a way, that normal

IRUN is 16 to 31 for best microstep performance.

IHOLDDELAY

Controls the number of clock cycles for motor

power down after a motion as soon as standstill is

detected (stst=1) and TPOWERDOWN has expired.

The smooth transition avoids a motor jerk upon

power down.

0:

1..15:

W

R

W

0x11

0x12

0x13

8

20

20

www.trinamic.com

TPOWER

DOWN

TSTEP

TPWMTHRS

instant power down

Delay per current reduction step in multiple

of 2^18 clocks

TPOWERDOWN sets the delay time after stand still (stst) of the

motor to motor current power down. Time range is about 0 to

4 seconds.

0…((2^8)-1) * 2^18 tCLK

Actual measured time between two 1/256 microsteps derived

from the step input frequency in units of 1/fCLK. Measured

value is (2^20)-1 in case of overflow or stand still.

All TSTEP related thresholds use a hysteresis of 1/16 of the

compare value to compensate for jitter in the clock or the step

frequency. The flag small_hysteresis modifies the hysteresis to

a smaller value of 1/32.

(Txxx*15/16)-1 or

(Txxx*31/32)-1 is used as a second compare value for each

comparison value.

This means, that the lower switching velocity equals the

calculated setting, but the upper switching velocity is higher as

defined by the hysteresis setting.

In dcStep mode TSTEP will not show the mean velocity of the

motor, but the velocities for each microstep, which may not be

stable and thus does not represent the real motor velocity in

case it runs slower than the target velocity.

This is the upper velocity for stealthChop voltage PWM mode.

TSTEP ≥ TPWMTHRS

- stealthChop PWM mode is enabled, if configured

- dcStep is disabled

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

28

VELOCITY DEPENDENT DRIVER FEATURE CONTROL REGISTER SET (0X10…0X1F)

R/W

W

Addr

0x14

n

20

Register

TCOOLTHRS

Description / bit names

This is the lower threshold velocity for switching on smart

energy coolStep and stallGuard feature. (unsigned)

Set this parameter to disable coolStep at low speeds, where it

cannot work reliably. The stall detection and stallGuard output

signal becomes enabled when exceeding this velocity. In nondcStep mode, it becomes disabled again once the velocity falls

below this threshold.

TCOOLTHRS ≥ TSTEP ≥ THIGH:

- coolStep is enabled, if configured

- stealthChop voltage PWM mode is disabled

TCOOLTHRS ≥ TSTEP

- stallGuard status output signal is enabled, if

configured

This velocity setting allows velocity dependent switching into

a different chopper mode and fullstepping to maximize torque.

(unsigned)

The stall detection feature becomes switched off for 2-3

electrical periods whenever passing THIGH threshold to

compensate for the effect of switching modes.

W

0x15

20

THIGH

TSTEP ≤ THIGH:

- coolStep is disabled (motor runs with normal current

scale)

- stealthChop voltage PWM mode is disabled

- If vhighchm is set, the chopper switches to chm=1

with TFD=0 (constant off time with slow decay, only).

- chopSync2 is switched off (SYNC=0)

- If vhighfs is set, the motor operates in fullstep mode

and the stall detection becomes switched over to

dcStep stall detection.

microstep velocity time reference t for velocities: TSTEP = fCLK / fSTEP

www.trinamic.com

�TMC2130 DATASHEET (Rev. 1.10 / 2018-MAY-09)

29

5.3 SPI Mode Register

This register cannot be used in STEP/DIR mode.

SPI MODE REGISTER (0X2D)

R/W

Addr

n

Register

Description / bit names

direct_mode

0:

Normal operation

1:

Directly SPI driven motor current

Range [Unit]

±255

for both coils

Direct mode operation:

XDIRECT specifies Motor coil currents and

polarity directly programmed via the serial

interface. Use signed, two’s complement

numbers.

RW

0x2D

32

XDIRECT

Coil A current (bits 8..0) (signed)

Coil B current (bits 24..16) (signed)

Range: +-248 for normal operation, up to +-255

with stealthChop

In this mode, the current is scaled by IHOLD