DSX321G 12MHz 12PF 20PPM 数据手册

Serial No. : 2014-0416

DATE : 2014/04/04

Lierda Science & Technology Group Co.,Ltd.

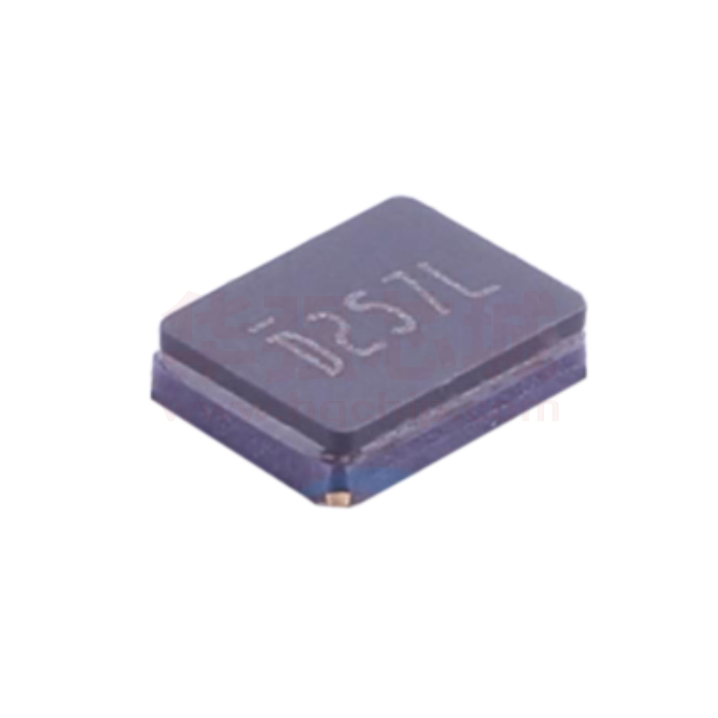

CRYSTAL RESONATOR

ITEM :

DSX321G 12.000MHz

----- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ----

(INDONESIA) 1C212000BC0AK

----- ---------- ---------- ---------- ---------- ---------- ---------- --------- ---------- ---------- ---------- ---------- ---------- ----

(THAILAND)

1N212000BC0AK

----- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ----

----- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ---------- ----

RECEIPT

DATE

RECEIVED

(signature)

(name)

General Manufacture� of Quartz Devices

1389 Shinzaike, Hiraoka-cho, Kakogawa, Hyogo

675-0194 Japan

Phone (81)79-425-3141 Fax (81)79-425-1134

http://www.kds.info/index_en.htm

C.ENG.

ENG.

�2014-0416

Serial No.

1. ELECTRICAL CHARACTERISTICS

(This test shall be performed under the conditions of temp.at +25 ± 3°C, Relative Humidity 60% max.)

(1) NOMINAL FREQUENCY

12.000000 MHz

(2) OVERTONE ORDER

Fundamental

(3) LOAD CAPACITANCE(CL)

12.0 pF

(4) FREQUENCY TOLERANCE

±20 ppm max. (at +25 ± 3 °C)

(5) DRIVE LEVEL

175 ±

10 μW

80 Ω max. (at Series)

(6) SERIES RESISTANCE

(7) OPERATING TEMPERATURE RANGE

-10

~ +70 °C

(8) FREQUENCY CHARACTERISTICS

±30 ppm max.

/

-10

~ +70 °C

(ref. to +25°C)

OVER TEMPERATURE

2.0pF max.

(9) SHUNT CAPACITANCE

(10) INSULATION RESISTANCE

(11) STORAGE TEMPERATURE RANGE

500MΩ min. / DC 100 ± 15V

-40

~ +85 °C

2. CONSTRUCTION

(1) DIMENSIONS AND MARKING

Refer to 4.

3. OTHER SPECIFICATIONS

(1) EMBOSS CARRIER TAPE & REEL

Refer to 5.

(2) PACKING

Refer to 6.

(3) REFLOW CONDITIONS (REFERENCE)

Refer to 7.

(4) LAND PATTERN (REFERENCE)

Refer to 8.

(5) RELIABILITY SPECIFICATION

Refer to 9. ~ 11.

(6) OTHER

HANDLING INSTRUCTIONS

Refer to 12.

TITLE

DSX321G TYPE QUARTZ CRYSTAL SPECIFICATION

REMARK

SPEC. No.

DATE

1C212000BC0AK

1N212000BC0AK

2014/04/04

DAISHINKU CORP.

REV.

PAGE

1 / 12

DM-Z0002:Style-010

�Serial No.

2014-0416

4. DIMENSIONS AND MARKING

(1) (2) (3)

0.75+/-0.15

2.5+/-0.1

3.2+/-0.1

(Internal connections)

2.1

#2

#4

#3

#3

#1

#2

#1 ,#3 Connected to quartz element

#2 ,#4 Open (unconnected)

0.7

1.6

#1

#4

0.9

Unit : mm

Tolerance : ±0.1

Figure-1

Logo(1) and Nominal Frequency (2) should be printed as follows by producing district

Made in INDONESIA

-->

Spec. No.:

1C212000BC0AK

, Logo : D

, Frequency: 12

Made in THAILAND

-->

Spec. No.:

1N212000BC0AK

, Logo : D

, Frequency: 12

_

* Made in INDONESIA

* Made in THAILAND

: Under Bar with D

: Top Bar with D

Nominal Frequency ( 2 ) = Mark two digits from upper decimal point

(ex. 12.000000 MHz ----> 12 )

Manufacturing lot No.( 3 )

2014

(year) ex.

Apr.

(Month)ex.

(Table-1.)

Month Jan.

Mark

A

Feb.

B

shall be marked as '

shall be marked as '

Mar.

C

Apr.

D

May.

E

4

D

Jun.

F

' (The last digit of the year)

' (As shown in Table-1.)

Jul.

G

Aug.

H

Sep.

J

Oct.

K

Nov.

L

Dec.

M

Plating material of a terminal. : Ni Plating + Au Plating.

A clearance between the soldering terminal portion and a print circuit board side should be less than 0.1mm.

TITLE

DSX321G TYPE QUARTZ CRYSTAL SPECIFICATION

REMARK

SPEC. No.

DATE

1C212000BC0AK

1N212000BC0AK

2014/04/04

DAISHINKU CORP.

REV.

PAGE

2 / 12

DM-Z0002:Style-010

�Serial No.

2014-0416

5. EMBOSS CARRIER TAPE & REEL

3.5+/-0.05

D249B

0.25+/-0.05

1.75+/-0.1

1.55dia.+/-0.05

4.0+/-0.1

8.0+/-0.2

3.5+/-0.1

(1) Dimensions of embossed carrier tape

1.15 dia.+/-0.05

2.0+/-0.05

4.0+/-0.1

1.0+/-0.1

2.8+/-0.1

User Direction of feed

(Unit : mm)

Figure-2

(2) Dimensions of tape reel

U

F3

θ

θ

E

F2

V

B

A

C

F1

W2

W1

Figure-3

TITLE

DSX321G TYPE QUARTZ CRYSTAL SPECIFICATION

REMARK

SPEC. No.

DATE

1C212000BC0AK

1N212000BC0AK

2014/04/04

DAISHINKU CORP.

REV.

PAGE

3 / 12

DM-Z0002:Style-010

�Serial No.

2014-0416

(Unit:mm)

Item

Mark

Dimensions Angle

Diameter

A

Φ180 +0.0 / -3.0

Inside of Frange

W1

9.0 ± 0.3

Outside of Frange

W2

11.4 ± 1.0

Inside Diameter

B

Φ60 +1.0-0

F1

3.0 ± 0.2

F2

4.0 ± 0.2

F3

5.0 ± 0.2

Length

V

11.9 +0.5 / -0.0

Angle

θ

120°

Spindle Diameter

C

Φ13 ± 0.2

Width

E

2.0 ± 0.5

Length

U

10.5 ± 0.4

Angle

θ

120°

Flange

Width

Center

Core Slit

Center

Core

Key Seats

(3) Material of the reel

Polystyrene+Carbon( Black )

Reel

Polystyrene(White)

(4) Storage condition

Temperature : +40 °C max.

Relative Humidity : 80% max.

( It is a guaranteed term because it obtains an excellent soldering: 6 months)

(5) Standard packing quantity

3,000 pcs/reel

(6) Material of the tape

Tape

Material

Carrier tape

Polystyrene+Carbon

Cover tape

Polyester

TITLE

DSX321G TYPE QUARTZ CRYSTAL SPECIFICATION

REMARK

SPEC. No.

DATE

1C212000BC0AK

1N212000BC0AK

2014/04/04

DAISHINKU CORP.

REV.

PAGE

4 / 12

DM-Z0002:Style-010

�Serial No.

2014-0416

(7) Label contents

Type

Our specification No.

Your Part No.

Lot No.

Nominal Frequency

Quantity

Our Company Name

Producting Country

Stick a label on the each reel.

(8) Taping dimension

Cover-tape

Leader

Carrier-tape

Cover-tape

Terminal

Carrier-tape

The length of cover-tape in the leader is more than 400mm

including empty embossed area.

After all products were packaged, must remain more than twenty pieces

or 400mm empty area, which should be sealed by cover-tape.

The tip of cover-tape shall be fixed temporary by paper tape and roll around

the core of reel one round.

The empty embossed area which are sealed by cover-tape must remain

more than 40mm.

Terminal

Leader

Components

Empty Components Unreeling direction

Empty Components

Cover-tape

Carrier-tape

Figure-4

(9) Joint of tape

The carrier-tape and cover-tape should not be jointed.

(10) Release strength of cover tape

It has to between 0.1 ~ 0.7N under following condition.

Pulling direction

165 ~ 180 °

Speed

300mm/min

Otherwise unless specified.

165 ~ 180 °

Pulling direction

Figure-5

Other standards shall be based on JIS C 0806 -1990.

TITLE

DSX321G TYPE QUARTZ CRYSTAL SPECIFICATION

REMARK

SPEC. No.

DATE

1C212000BC0AK

1N212000BC0AK

2014/04/04

DAISHINKU CORP.

REV.

PAGE

5 / 12

DM-Z0002:Style-010

�Serial No.

2014-0416

6. PACKING

(1) STORAGE METHOD

Label contents

The type of product

Lot No.

Specification

Quantity

Shipment Day

Remark

Label

Figure-6

(2) BOX SIZE

From lot size packingsize shall be changed.

In the upper and lower part and the opening in box it shall be protected products using

aircushion sheets.

TITLE

DSX321G TYPE QUARTZ CRYSTAL SPECIFICATION

REMARK

SPEC. No.

DATE

1C212000BC0AK

1N212000BC0AK

2014/04/04

DAISHINKU CORP.

REV.

PAGE

6 / 12

DM-Z0002:Style-010

�Serial No.

2014-0416

7. REFLOW CONDITIONS (REFERENCE)

During the solder reflow process, please complete within following temperature, period.

Reflow soldering shall be allowed only 2 times.

+260 ± 5 °C

+220 ± 5 °C

+160 ~ +180 °C

10 s

120 s

60 s

Total time : 240 s max.

Figure-7

HANDSOLDERING METHOD : +350 ± 10 °C , 3+1/-0s Each terminal once

(Please take care so that a soldering iron should not touch a product directly.)

8. LAND PATTERN (REFERENCE)

1 .2

1 .7

2 .2

1 .4

Unit : mm

Figure-8

TITLE

DSX321G TYPE QUARTZ CRYSTAL SPECIFICATION

REMARK

SPEC. No.

DATE

1C212000BC0AK

1N212000BC0AK

2014/04/04

DAISHINKU CORP.

REV.

PAGE

7 / 12

DM-Z0002:Style-010

�Serial No.

2014-0416

9. MECHANICAL ENDURANCE

(1) SHOCK (ACCELERATION)

After the following test,parts shall conform specification 11.C

1000m/s2 by 6ms X,Y,Z each axis (6 directions) , 3cycles

(2) SHOCK (MOUNTING DROP)

After the following test,parts shall conform specification 11.C

3cycles(18times) drop from 150 cm heights to concrete.

Further,parts shall be solderd on substrate, fixed Aluminum materials(about 100g).

Substrate materials

: Glass Epoxy

1 cycle

: each 1 times of 6 directions

(3) VIBRATION

After the following test,parts shall conform specification 11.C

and no abnormal appearance shall be observed.

Frequency of Vibration

: 10 ~ 500 ~ 10 Hz

Amplitude(p-p)

: Sine waves of 1.5mm or 100m/s 2

Cycle

: 11min

Vibration axis

: X.Y.Z

Vibration period

: 2 h for each axis

(4) SEAL

Less than 2.0×10-9 Pa m3/s by Helium leak detector.

Also, no serial bubble is observed by Fluorocarbon tests.

(5) SOLDERABILITY

After the following test, more than 95% of terminal shall be covered by new solder.

3 ± 0.5 s dip in +245 ± 5 °C solder.

(Solder composition : Sn-3Ag-0.5Cu) (Use rosin type flux for solder.)

(6) RESISTANCE TO SOLDERING HEAT (REFLOW)

48 h past at room temperature from following test,parts shall conform specification 11.C

perform the attached Reflow conditions to reference.

(7) RESISTANCE TO SOLDERING HEAT (HAND SOLDERING METHOD)

48 h past at room temperature from following test,parts shall conform specification 11.C

+350 ± 10°C , 3+1/-0s Each terminal once.

(8) SUBSTRATE BENDING

After the following test,parts shall conform specification 11.C

and no abnormality shall be observed in external appearance and sealing

tightnen and others shall be based on ET-7403 of EIAJ.

Mount the specimen on substrate.

Apply the following pressure

Direction

: see right figure

Speed

: about 1.0 mm/s

Hours

: 5±1s

pr essur e j i g

Amount of substrate

: 3 mm max.

20

R230

P. C. B.

45+/ - 2

TITLE

DSX321G TYPE QUARTZ CRYSTAL SPECIFICATION

45+/ - 2

REMARK

SPEC. No.

DATE

1C212000BC0AK

1N212000BC0AK

2014/04/04

DAISHINKU CORP.

REV.

PAGE

8 / 12

DM-Z0002:Style-010

�2014-0416

Serial No.

(9) SHEAR

After the following test,parts shall conform specification 11.C

and no abnormality shall be observed in external appearance and sealing

tightness and others shall be based on ET-7403 of EIAJ.

P. C. B.

Mount the specimen on substrate.

Apply the following pressure

Weight

: 10 N

Hours

: 10 ± 1 s

Direction : see right figure

pr essur e j i g

R0. 5

speci men

(10) BODY STRENGTH

After the following test,parts shall conform specification 11.C

and no abnormality shall be observed in external appearance and sealing

tightness and others shall be based on ET-7403 of EIAJ.

Mount the specimen on substrate.

Apply the following pressure

Presure jig : R0.5

Weight

: 10N

Hours

: 10 ± 1 s

Direction : see right figure

pr essuer

j i g

R0. 5

s peci men

W

L

L > = W

0. 5L

L

TITLE

DSX321G TYPE QUARTZ CRYSTAL SPECIFICATION

REMARK

SPEC. No.

DATE

1C212000BC0AK

1N212000BC0AK

2014/04/04

DAISHINKU CORP.

REV.

PAGE

9 / 12

DM-Z0002:Style-010

�Serial No.

2014-0416

10. ENVIRONMENTAL ENDURANCE

(1) LOW TEMPERATURE

2 h past at room temperature after following test, parts shall conform specification 11.C

240 h , -40 ± 3 °C.

(2) HUMIDITY

2 h past at room temperature after following test, parts shall conform specification 11.D

240 h , +85 ± 2 °C , relative humidity 85 ± 5%.

(3) HIGH TEMPERATURE

2 h past at room temperature after following test, parts shall conform specification 11.D

240 h , +85 ± 2 °C.

(4) TEMPERATURE CYCLE

2 h past at room temperature after 25 cycles of following test, parts shall conform specification 11.D

30min

+85°C

+25°C

Transport Time

2-3min

30min

-40°C

1 cycle

11. SPECIFICATION

Frequency Variation and Equivalent Resistance shall be within Table below after the reliability test.

Spec.

A

B

C

D

E

Frequency Variation

±2ppm

±5ppm

±5ppm

±10ppm

±20ppm

Equivalent Resistance

±15 % or 2.0 Ω max. (Use larger specification)

±15 % or 2.0 Ω max. (Use larger specification)

±20 % or 3.0 Ω max. (Use larger specification)

±20 % or 3.0 Ω max. (Use larger specification)

±25 % or 10.0 Ω max. (Use larger specification)

TITLE

DSX321G TYPE QUARTZ CRYSTAL SPECIFICATION

REMARK

SPEC. No.

DATE

1C212000BC0AK

1N212000BC0AK

2014/04/04

DAISHINKU CORP.

REV.

PAGE

10 / 12

DM-Z0002:Style-010

�Serial No.

2014-0416

12. DSX321G TYPE QUARTZ CRYSTAL HANDLING INSTRUCTIONS

(1) SOLDERING

Please perform the attached Reflow conditions to reference within 2 times.

(2) MOUNT

Crystal products are designed to be compatible with automatic mounting.

Be sure to have a mounting test in advance by using the actual mounting machine

and check that the characteristics of the products are not damaged

by the automatic mounting.

In the process where the boad is warped, such as board separation process,

be careful that the warping does not influence the characteristics

and soldering of crystal products.

Since mounting by Ultrasonic welding and processing have a possibility of an excessive

vibration spreading inside a crystal resonator and becoming the cause of characteristic

deterioration and not oscillating, it does not recommend.

Underfilling Material for DSX321G Types,KDS considers underfilling material such as heat-cured resin

would not affect the characteristics of the DSX321G crystal mounted, however, we recommend the crystal

be tested and checked in such a case prior to use so that there are the possibility that the crystal may have

a cap off or a crack in the ceramic base.

(3) WASHING

About use of the washing liquid of a basin system,

an alcoholic system, and a chlorofluorocarbon-replacing

material system, it is checking that it is satisfactory.

However please consult in advance about other washing liquid.

Although the check about ultrasonic washing is performed,

since it is an examination with a simple substance,

the check for the second time by the use state is recommended.

(4) THE CAUTIONS ON USE

The piece of crystal it is processed very smaller than the conventional thing

inside DSX321G series crystal unit may be damaged,

if excessive excitation electric power is applied.

Please use it below with the value specified on a catalog and specifications.

Please refrain from forming patterns between crystal land pattern's since there is

a possibility to cause crack in base.

If the temperature is higher than +280 °C, there is a possibility for the sealing glass to remelt.

Avoid using the product at temperature higher than specified.

(5) HANDLING OF A PRODUCT

DSX321G series has sufficient intensity to fall and vibration.

However when too much shock is added according to a certain cause,

the use after a characteristic check is recommended.

(6) STORAGE

Since the soldering nature of a terminal may be degraded,

please avoid storage in high temperature and a humid place.

Please keep it in the place which direct rays do not hit

and dew condensation does not generate.

TITLE

DSX321G TYPE QUARTZ CRYSTAL SPECIFICATION

REMARK

SPEC. No.

DATE

1C212000BC0AK

1N212000BC0AK

2014/04/04

DAISHINKU CORP.

REV.

PAGE

11 / 12

DM-Z0002:Style-010

�2014-0416 REVISION RECORD

Rev.No

Date

Reason

-

2014/04/04

-

Contents

The first edition.

- 12 / 12 -

Approved

Checked

Drawn

T.Okishio

Y.Maeda

S.Miura

DM-Z0002:Style-005

�