PRODUCT SPECIFICATION OF OUPIIN

PRODUCT

SPECIFICATION

(產品規格書)

Ordering information

2115- 1X

Series

G

00

D

A-L2

U

1:Single No. of

G:Gold Plated 00:Gold Flash D:SMD Type

A:A Type U:Tube Package

Row

T:Tin Plated

B:B Type

2115- 2X

Series

40

Pin Count

40

2:Double No. of

Row

G

00

D

N-L2

U

G:Gold Plated 00:Gold Flash D:SMD Type N﹕Without Post U:Tube

Pin Count T:Tin Plated

P﹕With Post

Package

L2:Mating Length

A2:APR.12/2011

A3:JAN.06/2016(絕緣)

PRODUCT NAME

(產品名稱)

DOCUMENT No.:

(文件編號)

Rev.

(版本)

OUPIIN

PIN HEADER

2115spec

A3(I535)

(歐品)

2.0 mm

Approved

(核準)

Checked

(審核)

Prepared

(製作)

Q.A. Section Chief

Sunny Tsai

JAN.06/2016

2.0 mm*2.0 mm

(RoHS)

Page 1/11

�PRODUCT SPECIFICATION OF OUPIIN

1. SCOPE(範圍) .................................................................................................................... 3

2. REFERENCE DOCUMENTS(参考文件) ..................................................... 3

3. FEATURE & DIMENSIONS(特徵及尺寸) .................................................. 3

3.1. PRODUCT DIMENSION (產品尺寸)......................................................................................... 3

3.2. PCB/PANEL LAYOUT(印刷電路板佈局) ................................................................................... 3

3.3. BILL OF MATERIAL(材料清單) ................................................................................................ 3

3.4. MECHANICAL & ELECTRICAL CHARACTERISTIC(機械及電器特性)................................... 3

3.5. PACKAGING(包裝) .................................................................................................................. 3

3.6 RATING CURRENT AND RATING VOLTAGE (額定電流與額定電壓) ........................................ 4

3.7 STORAGE AND OPERATING TEMPERATURE (儲存使用溫度)) .............................................. 4

4. Environmental(環境要求) ...................................................................................... 4

4.1. SOLDERABILITY(可焊性) ....................................................................................................... 4

4.2. RESISTANCE TO SOLDER HEAT(耐焊接熱) ......................................................................... 4

4.2.1. INFRARED REFLOW(紅外線回流焊接) ................................................................................... 4

1.Preheat(預熱) ............................................................................................................................... 4

2 Soldering(焊接) ............................................................................................................................. 4

3 Cool Down(冷却) .......................................................................................................................... 4

5. PERFORMANCE AND TEST DESCRIPTION(性能及測試) ...... 5

5.1. REQUIREMENT(要求) ............................................................................................................. 5

5.2. TEST CONDITION(測試條件) .................................................................................................. 5

5.3. SAMPLE SELECTION(樣品選擇)............................................................................................. 5

Table I:

Test Requirements and Procedure ............................................ 6- 7

(附錄一: 測試要求)

Table II:

Reflow soldering profile .......................................................................... 8

(附錄二: 回流焊接曲線圖)

Table III:

Material

(附錄三:

材料證明)

............................................................................................................ 9-11

Page 2/11

�PRODUCT SPECIFICATION OF OUPIIN

1. SCOPE (範圍)

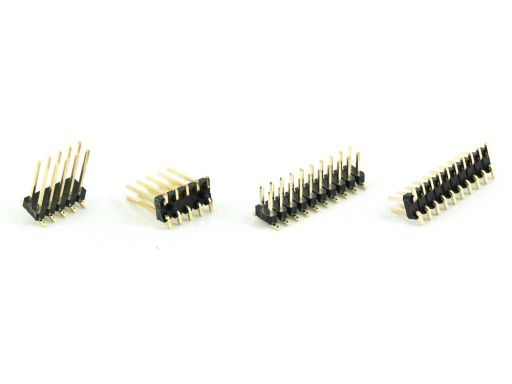

This product specification defines the product performance and the test methods to ascertain the

performance of the PIN HEADER 2.0 mm*2.0 mm connector, which is designed and manufactured by Oupiin

Electronic Co.,Ltd.

(本產品規格書規定了由歐品電子有限公司生產的 PIN HEADER 2.0mm*2.0mm connector

型連接器,產品的特性及測試方法.)

2. REFERENCE DOCUMENTS (參考文件)

MIL-STD-1344A

Test method for electrical connector

(電子連接器測試方法)

MIL-STD-202

Test method for electrical components

(電子零件測試方法)

EIA 364

Test method for electrical components

(電子零件測試方法)

3. FEATURE & DIMENSIONS (特徵及尺寸)

3.1. PRODUCT DIMENSION (產品尺寸)

These connectors shall have the dimensions as shown in drawing.

(本產品的相關尺寸參考圖面.)

3.2. PCB/PANEL LAYOUT (印刷電路板佈局)

The recommended PCB layout is shown in drawing.

(本產品適用的 PCB layout 參考圖面.)

3.3. BILL OF MATERIAL (材料清單)

Harmful material control follow the requirement of RoHS. The bill of material and product number is

described in drawing.

(有害物質控制符合RoHS指令要求.本產品使用的材料參考附件.)

3.4. MECHANICAL & ELECTRICAL CHARACTERISTIC(機械及電氣特性)

The connector shall have the mechanical and electrical performance as described in drawing.

(本產品的機械及電氣特性見圖面:)

3.5. PACKAGING (包裝)

Products shall be packaged according to requirements specified in purchase order for safe delivery,

connector container and the packaging method are shown in package specification.

Page 3/11

�PRODUCT SPECIFICATION OF OUPIIN

(產品可依客戶指定要求包裝,包裝材料與包裝方式參見產品包裝規範。)

3.6 RATING CURRENT AND RATING VOLTAGE 額定電流與額定電壓

Rating current is 2.0A, rating voltage is 125V DC/AC RMS.

額定電流 2.0A,額定電壓 150V DC/AC RMS。

3.7 STORAGE AND OPERATING TEMPERATURE 儲存與使用溫度

Temperature range: -40°C~+105°C, including terminal temperature rise for rating current.

溫度範圍:-40°C~+105°C,包含接觸端子的額定電流溫升。

4. ENVIRONMENTAL(環境要求)

4.1. SOLDERABILITY (可焊性)

Connectors meet solder ability to MIL-STD-202F. Finish shall be free of contaminants.

(產品可焊性符合 MIL-STD-202F 標準規定的相關要求,表面不得有污染物.)

4.2. RESISTANCE TO SOLDER HEAT (耐焊接熱)

INFRARED REFLOW (紅外線回流焊接)

Three cycles. Each cycle consisting of three consecutive phased.

(三個週期,每個週期包括三個連續的階段完成;)

1. Preheat (預熱)

Increase in temperature not to exceed 4℃ per second.

(溫度增加不超過 4℃ /秒,)

2. Soldering (焊接)

Maximum allowable time above reflow temperature of 150~200℃ is 90~120 seconds. Maximum

temperature in this interval is 260℃, not to exceed 5 seconds.

(回流焊溫度150~200℃時最長不超過90~120秒. 最高溫度260℃時間不超過5秒.)

3. Cool Down (冷卻)

Cool down shall not exceed 6℃ per second.

(冷卻速度不超過6℃/秒.)

Note: (說明)

Device temperature measurements are referenced from the top-center of the package outer surface.

(設備溫度量測時以從頂部中間位置測量為准.)

Page 4/11

�PRODUCT SPECIFICATION OF OUPIIN

5. PERFORMANCE AND TEST DESCRIPTION

(性能及測試)

5.1. REQUIREMENT (要求)

Product is designed to meet electrical, mechanical, and environmental performance requirements

specified in Table I.

(本產品設計符合附表一所列的機械,電氣及環境要求.)

5.2. TEST CONDITION

(測試條件)

Unless otherwise specified, all tests shall be performed at ambient environmental conditions.

(除非特別注明,所有測試在室溫條件下完成;)

5.3. SAMPLE SELECTION

(樣品選擇)

Test samples shall be selected at random from current production. No test samples shall be reused.

Samples are pre-conditioned with 10cycles of durability. Each group shall be containing 5 test samples.

(測試樣品從現生產的產品中隨機抽取,所有測試過的樣品不得重複使用. 樣品已預先插拔10次,每組測試

有5個樣品;)

Page 5/11

�PRODUCT SPECIFICATION OF OUPIIN

Table I:

Test Requirements and Procedures

(附錄一:測試要求)

Items

(項目)

1. Confirmation of

Requirements

(要求)

Test Methods

(檢測方法)

Product shall be conforming to the

Check the dimensions and functions per applicable

Product

requirements of applicable product

product drawing in your eyes.

(產品確認)

drawing.

(目視,尺寸及功能依產品圖面檢查)

(產品必須滿足相關檔的規定)

2. Contact

Resistance

20 mΩ Max. initial

Subject mated contacts assembled in housing to

(最大.初態)

closed circuit of

(接觸阻抗)

100 mA max. at open circuit

voltage of 10 mV max.

(所述固定在外殼裏的端子連結到一個封閉回路中測

試:電流 100 mA,電壓 10 mV max.)

3. Insulation

Resistance

5000 MΩ Min.

Measure by applying test potential between the

(最小)

adjacent contacts, and between the contacts and

(絕緣阻抗)

ground in the mated connector.

MIL-STD-202, Method 302,

Condition B (500 V DC±10%).

(測試產品端子間以及端子與接地間的電阻,適用:

MIL-STD-202,方法 302,條件 B )(500V DC±10%)

4. Dielectric

Connector must withstand test

Measure by applying test potential between the

Strength

potential of 500 V AC for 1 minute.

adjacent contacts, and between the contacts and

(耐電壓)

Current leakage must be 0.5 mA max. ground in the mated connector. MIL-STD-202,

(樣品必須承受測試電壓 500V AC,時間 Method 301.

一分鐘,漏電流不大於 0.5 mA.)

(測試產品端子間以及端子與接地間的電壓,適用:

MIL-STD-202,方法 301。)

5. Thermal

After testing, no damage, Contact

Temperature range from -40°C to +85°C .Start from

shock

Resistance 30 mΩ max.. Dielectric

-40°C, after 30 min. change to +85°C; change time

(熱衝擊)

Strength should be OK, Insulation

is no more than 30 seconds. Total 5 cycles.

Resistance should be 5000 MΩ min. MIL-STD-202, Method 107D, condition A.

(測試後,產品無損壞,接觸阻抗:30 m (溫度變化範圍: -40°C~ +85°C;從 -40°C 開始,

Ω最大;耐電壓測試 OK, 絕緣阻抗 30 分鐘後換到+85°C;轉換時間不超過 30 秒;共 5

5000MΩ最小;)

6. Humidity

After testing, no damage, Contact

個循環.適用:MIL-STD-202,方法 107D,條件 A.)

Temperature :85±2°C 96 hours.

Page 6/11

�PRODUCT SPECIFICATION OF OUPIIN

(恆溫恆濕)

Resistance 30 mΩ max.. Dielectric

(溫度:85±2°C 96 小時)

Strength should be OK, Insulation

Relative Humidity : 90-95%;

Resistance should be 5000 MΩ min. (相對濕度 :90-95%;)

(測試後,產品無損壞,接觸阻抗:30 m Duration :96 Hours. MIL-STD-202, Method 108,

Ω最大;耐電壓測試 OK, 絕緣阻抗 (時間:96 小時;MIL-STD-202,方法 108。)

5000MΩ最小;)

7.High temperature After testing, no damage, Contact

(高溫)

Subject product to 85±2°C for 96 hours

Resistance 30 mΩ max.. Dielectric

continuously. MIL-STD-202, Method 108.

Strength should be OK, Insulation

(產品置於 85±2°C 連續 96 小時,適用 MIL-STD-202,

Resistance should be 5000 MΩ min.

方法 108。)

(測試後,產品無損壞,接觸阻抗:30 m

Ω最大;耐電壓測 試 OK, 絕緣阻 抗

5000MΩ最小;)

8. Solder ability

Appearance of the specimen shall be Soldering time: 3 to 5 Seconds

(可焊性)

inspected after the test with the

(焊接時間:3~5 秒)

assistance of a magnifier capable of

Peak Temperature: 245±5°C.

giving a magnification of 10 X for any (最高溫度:245±5°C.)

damage such as pinholes, void or

rough surface.

(樣品在測試完成後,在放大倍數為 10

倍的顯微鏡下,檢查外觀損壞如:小

孔,空焊,外觀粗糙度;)

9.Resistance to

No damage

Leave subject product in the 260±5°C chamber for

soldering heat

產品無損壞

5 Seconds

耐焊接热

產品置於 260±5°C 烘箱内 5 秒。

Page 7/11

�PRODUCT SPECIFICATION OF OUPIIN

Table II: Reflow soldering profile

(附錄二:回流焊接曲線圖)

Pb-free reflow profile requirements: (無鉛回流焊接曲線)

Parameter

(參數)

Reference

(參考)

Specification

(規格)

Average Temperature Gradient in

Preheating (平均預熱溫度)

Soak Time 25~150°C

Time Above 150~200°C

Time Above 200~230°C

Time Above 230~255°C

Peak temperature in reflow

(回流焊接中最高溫度)

2.5°C/s

Tsoak

t1

t2

t3

Tpeak

60 Seconds (max)

120 Seconds (max)

50 Seconds (max)

5 Seconds (max)

260°C (–0/+5°C)

Temperature Gradient in Cooling

(冷卻時溫度幅度)

Max -5°C/s

Not to scale, for reference only

Temperature

Temperatur

e

Tpeak

peak

T33

T22

T11

tsoak

t3

t3

t2

Time

t2

t1

This profile is the minimum requirement for evaluating soldering heat resistance of components. Heat

transfer method used for reflow soldering is hot air convection. The actual air temperatures used to

achieve the specified profile largely dependent on the reflow equipment.

(這個曲線圖是評估原器件焊接抗熱的基本要求. 應用在對流焊接中的熱傳遞方式是熱氣對流. 達到特定

曲線圖的實際溫度主要依賴於回流焊接設備.)

Page 8/11

�PRODUCT SPECIFICATION OF OUPIIN

Material Housing : 038-PA6T (E430NK)

SGS Test Report Click here

如需 SGS 測試報告請點選此處

Page 9/11

�PRODUCT SPECIFICATION OF OUPIIN

Material Housing :UL

Page 10/11

�PRODUCT SPECIFICATION OF OUPIIN

Material Contact :Copper Alloy (SQUAREPIN-Au)

SGS Test Report Click Here

如需 SGS 測試報告請點選此處

Page 11/11

�

很抱歉,暂时无法提供与“2115-2X22G00DN-4B”相匹配的价格&库存,您可以联系我们找货

免费人工找货