TJ-S3528RGSSZJLB88-A3 数据手册

GUANGDONGTONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

承 認 書

Specification For Approval

Customer: (客戶)

Description: (產品描述)

Part number:(產品型號)

Date:

SMD3528红翠绿

TJ-S3528RGSSZJLB88-A3

(日期)

Approved By: (客戶承認)

Prepared By:(我司承認)

Approval

核准

Check

Design

審核

製作

Sales

業務

Customer Service Hotline:400-676-8616

TEL:0769-8662 5999

0769-8200 2226

E-MIAL∶dg@togialed.com

FAX:0769-8200 2227

WEB:www.togi aled. c om

�GUANGDONGTONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

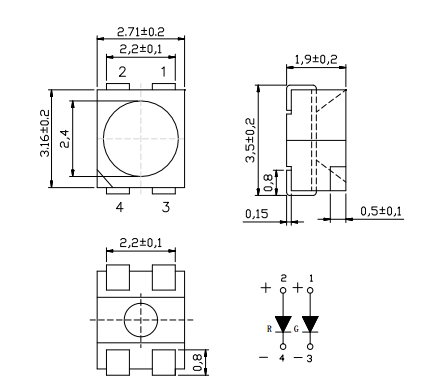

Package Dimensions(封装尺寸)

R

G

Recommended Soldering Patter (n 推荐焊盘式样)

Note :

1:All dimensions are in millimeters (inches).

2:Tolerance is ±0.25mm (.010”) unless otherwise noted.

3:

Specifications are subject to change without notices.

4:This specification is for reference only for one year

�GUANGDONGTONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

极限参数 Absolute maximum ratings

参数 Parameter

(Ta=25°C)

符号 Symbol

正向电流 Forward current

数值 Value

单位 Unit

If

40

mA

反向耐压 Reverse voltage

Vr

5

V

耗散功率 Power dissipation

工作环境温度 Operating temperature range

Pd

104

mW

Top

-25~+80

°C

贮藏温度 Storage temperature range

Tstg

-30~+85

°C

峰 值 脉 冲 电 流 Peak pulsing current ( 1/8 duty

f=1KHz)

Ifp

52

mA

Tj

115

℃/W

ESD

1000

V

结温 Junction Temperature

静电 Electrostatic Discharge(HBM)

(TA=25°C)

光电特性 Electro-Optical characteristics

测试条件

Test

Condition

符号

Symbo

l

颜色

色温

Color Temperature

正向电压

Forward voltage

IF=20mA

CCT

IF=20mA

光通量

luminous flux

参数

Parameter

数值 Value

单位 Unit

Min

Typ

Max

--

--

--

--

K

Vf

R

G

1.8

2.8

--

2.4

3.4

V

IF=20mA

φ

R

G

600

1500

--

800

2000

mcd

视角

Viewing angle at 50% IV

IF=20mA

2θ1/2

R

G

--

120

--

Deg

主波长

Dominant wavelength

IF=20mA

λd

R

G

620

520

--

630

530

nm

反向电流

Reverse current

显色性指数

Color Rendering Index

Vr=5V

Ir

R

G

--

5

--

μA

IF=20mA

CRI

--

--

--

--

Ra

�GUANGDONGTONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

典型的光电特性曲线图表 Typical photo-electricity characteristic curve chart

Forward Current VS.

Forward Voltage

Forward Current(mA)

Relative Luminous Intensity

Forward Current VS.

Relative Intensity

Forward Voltage(V)

Forward Current(mA)

Ambient Temperature VS.

Relative Intensity

Forward Current(mA)

Relative Luminous Intensity

Ambient Temperature VS.

Forward Current

0

20

40

60

80

100

Ambient Temperature Ta( °C)

0°

30°

50

0

50

90°

90°

20

60°

100

0

40

60

80

Ambient Temperature Ta( °C)

60°

30°

-20

100

Relative Luminous Intensity(%)

�GUANGDONGTONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

可靠性实验项目 Test items and results of reliability

Environmental

Sequence

类

别

Typ

e

测试项目

Test item

测试条件

Test Conditions

-25°C 30min

↑↓5min

80°C 30min

-25°C 15min

↑↓5min

80°C 15min

高低温循环

Temperature Cycle

JIS C 7021

(1977)A-4

热冲击

Thermal Shock

MIL-SLD-107D

高温度热循环

High Humidity Heat Cycle

JIS C 7021 (1977)A-5

高温存储

High Temperature Storage

高温高湿存储

Humidity Heat Storage

低温存储

Low Temperature Storage

备注

Note

不良数量

Number of

Damaged

100 cycle

22

0

50 cycle

22

0

30°C〈=〉65°C

90%RH 24hrs/1cycle

10 cycle

22

0

JIS C 7021 (1977)B-10

Ta=80°C

1000hrs

22

0

JIS C 7021 (1977)B-11

Ta=60°C

RH=90%

1000hrs

JIS C 7021 (1977)B-12

Ta=-30°C

1000hrs

JIS C 7035 (1985)

Ta=25°C

IF=20mA

1000hrs

22

0

高温高湿寿命测试

High Humidity Heat Life

Test

60°C RH=90%

IF=20mA

500hrs

22

0

低温寿命测试

Low Temperature Life Test

Ta=-25°C

IF=20mA

1000hrs

22

0

常温寿命测试 Life Test

Operation

Sequence

参照标准

Standard

数量

ity

Quantity

22

22

0

0

请参考可靠性测试标准规范。Refer to reliability test standard specification for in this line.

失效判定标准

Criteria For Judging Damage

测试项目

符号

测试条件

正向电压

Forward Voltage

VF

IF=IFT

反向电流

Reverse Current

IR

VR=5V

IR≦10μA

IF=IFT

平均 IV 衰减≦30℅,单个平均 IV 衰减≦50℅

Average IV degradation≦30℅

Single LED IV degradation≦50℅

--

材料无内部裂痕、无材料间爆裂、剥离、无死灯

Meterial without internal cracks, no material between

stripped, no deaded light.

光强

Luminous Intensity

耐焊接热

Resistance to Soldering Heat

IV

--

判定标准

初始值±10℅

Initial Data±10℅

*数据工作表中所示的技术信息仅限于典型特征和电路实例引用的产品.它既不构成工业特性的保证,也不构成任何许可的授权

The technical information shown in the data sheets are limited to the typical characteristics and circuit examples of the referenced products. It does not

constitute the warranting of industrial property nor the granting of any license.

�GUANGDONGTONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

焊接指导 Guideline for Soldering

1、 回流焊接:推荐以下无铅回流焊接温度图进行。

Reflow Soldering: Use the conditions shown in the under Figure of Pb-Free Reflow Soldering.

SMD-Reflow Soldering Profile for lead free soldering( Acc.to J-STD-020B)

300

℃

T

255℃

240℃

250

Maximum Solder Profile

Recommended Solder Profile

Minimum Solder Profile

217℃

200

+0℃

260℃ -5℃

245℃ ±5℃

235℃ +5℃

-0℃

10s min

30s max

Ramp Down

6K/s(max)

150

120s max

100s max

100

Ramp Up

3 K/s(max)

50

25℃

0

0

50

100

150

200

250

s

300

t

Remark:

If not lead free soldering, the recommended solder profile is 230℃and max solder profile is 245℃.

2、 使用烙铁人手焊接 Hand Soldering

1)、 推荐使用低功率于 20W 的烙铁,焊接时烙铁的温度必须保持在 360℃以下,且每个电极只能进行一次焊

接,每次焊接的持续时间不得超过 3 秒。

A soldering iron of less than 20W is recommended to be used in Hand Soldering Please keep the temperature of

the soldering iron under 360℃ while soldering Each terminal of the LED is to go for less than 3 second and for

onetime only.

2)、 人手焊接过程中的不慎操作易引起 LED 产品的损坏,应当小心谨慎。

Be careful because the damage of the product is often started at the time of the hand soldering.

3、 清洗 Cleaning

1)

、在焊接后推荐使用酒精进行清洗,在温度不高于 30℃的条件下持续 3 分钟,不高于 50℃的条件下持续

30 秒,使用其他类似溶剂清洗前,请先确认使用的溶剂不会对 LED 的封装和环氧树脂造成损伤。

It is recommended that alcohol be used as a solvent for cleaning after soldering. Cleaning is to go under 30℃

for 3 minutes or 50℃ for 30 seconds. When using other solvents, it should be confirmed beforehand whether the

solvents will dissolve the package and the resin or not.

2)、超声波清洗也是有效的方法,一般最大功率不应超过 300W,否则可能对 LED 造成损伤,请根据具

体的情况预先测试清洗条件是否会对 LED 造成损伤。

Ultrasonic cleaning is also an effective way for cleaning. But the influence of Ultrasonic cleaning on LED

depends on factors such an ultrasonic power. Generally, the ultrasonic power should not be higher than 300W.Before

cleaning, a pre-test should be done to confirm whether any damage to LEDs will occur.

�GUANGDONGTONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

编带和包装 Tape and Packaging

1、带盘 Tape leader and reel

M oisture Resistant Packaging

2. 2、防潮袋包装

防潮带包装

Moisture Resistant Packaging

Lable

A lum inum m oisture-proof bag

D esiccant

Lable

�GUANGDONGTONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

Operation precautions 操作注意事项

1.

It is suggested that reflow soldering should not be more than twice, and the temperature

curve should meet the standard, and the maximum temperature should not exceed 260 ℃;

回流焊建议不要超过两次,且温度曲线符合标准,最高不超过 260℃,避免胶体过度膨胀死灯;

2. In the process of operation, do not press the colloidal surface of the lamp bead in front. It is

recommended to use special tweezers to operate from the side;

在作业过程中,请勿正面按压灯珠胶体表面,建议使用专用镊子从侧面操作;

3. After reflow soldering, do not stack one side of PCB board containing exposed LED together.

External impact may scratch the colloid and cause damage to internal circuit;

回流焊后,不要将含有暴露 LED 的一面 PCB 板堆叠在一起,外部的冲击可能会划伤胶体导

致内部电路损坏;

4. After welding to PCB, it is not recommended to bend the PCB board, which may cause dark

crack of the bracket and not bright during assembly;

焊接到 PCB 板后,不建议弯曲 PCB 板,这样可能会造成支架出现暗裂,在组装时出现不亮;

5. In SMT, a proper suction nozzle should be larger than the luminous surface of the lamp bead

colloid to prevent damage to the colloid of the lamp bead or the internal circuit until the lamp is

not on;

SMT 时采用合适的吸嘴,应大于灯珠胶体发光面,防止损伤灯珠胶体或内部电路至死灯不亮;

6. Pay attention to static electricity when operating LED. If the static electricity is too high, it will

break down the internal chip, resulting in poor short circuit. Wear anti-static Bracelet during

operation, and the production machinery must be grounded;

操作 LED 时,注意静电,静电过大会击穿内部芯片,造成短路不良,作业时应佩戴防静电手

环,生产机械必须接地;

Precautions for use 使用注意事项

1. Please pay attention not to use in the environment with serious acid and alkali and sulfur ion

serious chemical sites, which may lead to excessive corrosion of LED colloid and bracket, and

eventually led does not light up;

请注意使用环境勿在带酸碱性严重以及硫离子严重的化工场所,这样可能会使 LED 胶体以及

支架过度腐蚀,最终导致 LED 不亮;

2. If it is used in humid environment or outdoor for a long time, waterproof work should be

done to avoid short circuit or dead light phenomenon of lamp bead due to damp;

如长期在潮湿环境下或室外使用,应做好防水工作,避免灯珠因受潮出现短路或死灯现象;

3. After the buyer receives the goods, according to the operation guidance, 100 lamp

beads in small batch trial production, confirm the quality and parameters of mass

production, so as to avoid losses, otherwise, the supplier will not compensate for expanded

losses. At the same time, the liability of the supplier is not more than the transaction

amount of the batch.

需方收货后,根据作业指导,100 个灯珠内小批量试产,确认品质及参数再批量生产,以免

造成损失,否则,对于扩大损失供方不予赔偿。同时,涉及供方责任,均不超当批次交易金

额。

�GUANGDONGTONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD

4. Please strictly refer to the electrical parameters recommended by our company to avoid

other adverse phenomena;

请严格参照我司建议的电性参数使用,避免出现其他不良现象;

5. Use in BIN area to avoid color mixing

分 BIN 区使用,以免造成混色

6. The shelf life of this product is 1 year

该产品保质期 1 年

7. Before using the product, please dehumidify and bake according to the moisture level of the

humidity card before use, so as to avoid the lamp bead reflow welding and death due to the

damp without dehumidification

使用该产品在使用前请根据湿度卡的受潮等级进行使用前的除湿烘烤,避免因为灯珠受

潮未除湿而造成灯珠过回流焊而死灯

8. In the use of LED lamp beads, heat dissipation should be done well. Long term work under

high temperature will accelerate the aging of LED lamp beads, light failure, and even death of

light;

LED 灯珠在使用工作过程中,应做好散热工作,长期在高温状态下工作,会使 LED 灯珠加速

老化,光衰,严重的会出现死灯不良;

�

TJ-S3528RGSSZJLB88-A3 价格&库存

很抱歉,暂时无法提供与“TJ-S3528RGSSZJLB88-A3”相匹配的价格&库存,您可以联系我们找货

免费人工找货